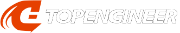

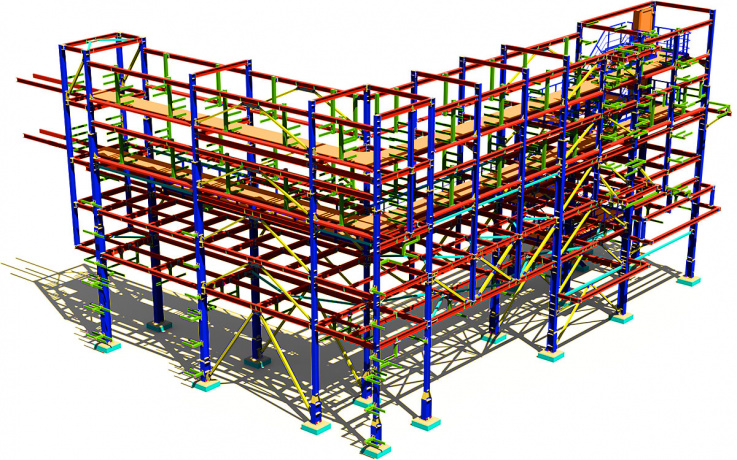

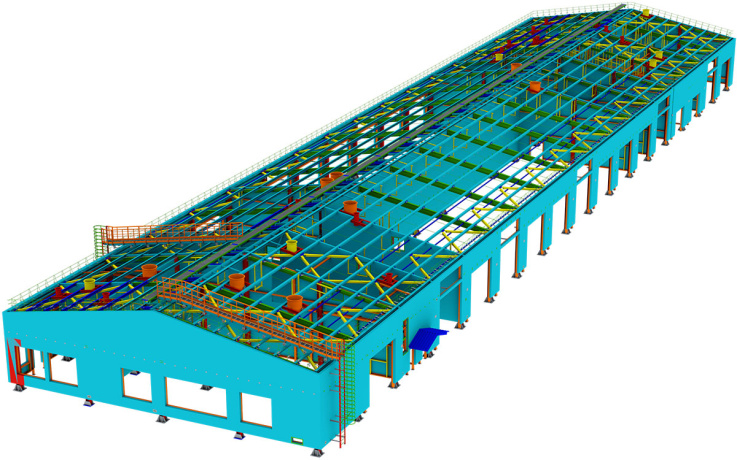

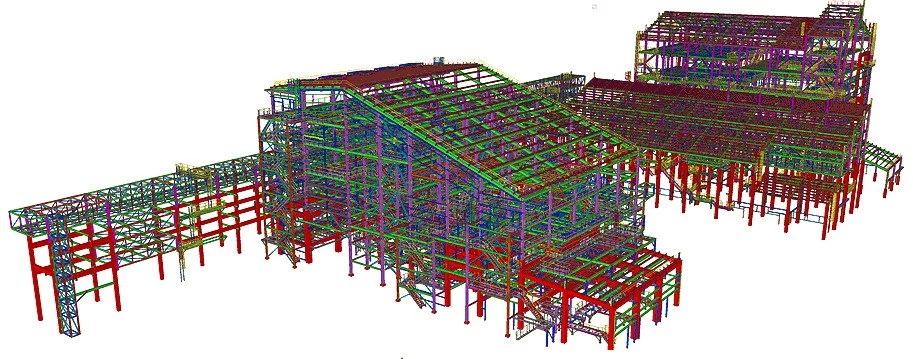

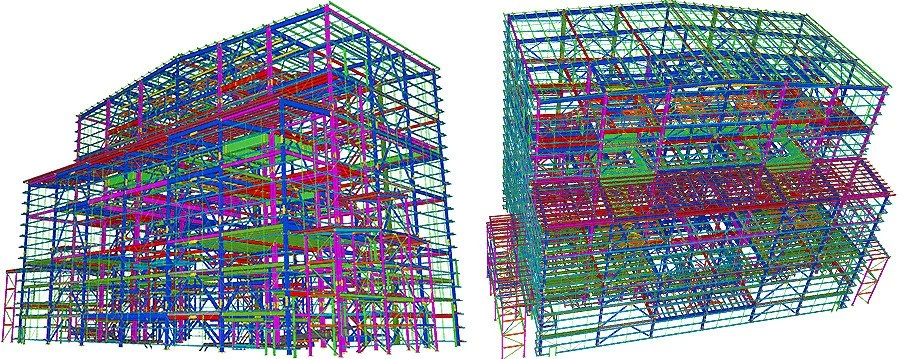

Structural detailing in Tekla for gas processing building

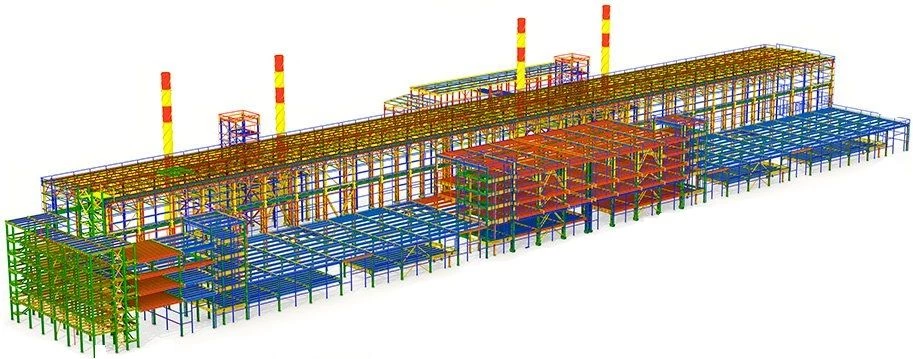

TopEngineer developed steel detailing (shop and erection drawings) for the needs of liquefied natural gas (LNG) plants. Documentation was developed for Technip company. The uniqueness of this project for our company was as follows: 1. As initial data, we were provided with a rod model with calculated sections and forces for joints. We, in turn, made the calculation of all connection for metal structures. 2.The design often changed in the project due to updated tasks from technologists. We tracked changes and adjusted drawings for steel fabricators or site workers.INFORMATION

| Dimensions | 75 m x 37 m |

|---|---|

| Building height | 51 m |

| Weight | 7 832 112 kg |

| Number of parts | 122 017 |

| Purpose | LNG |

| Documentation | Steel detailing |

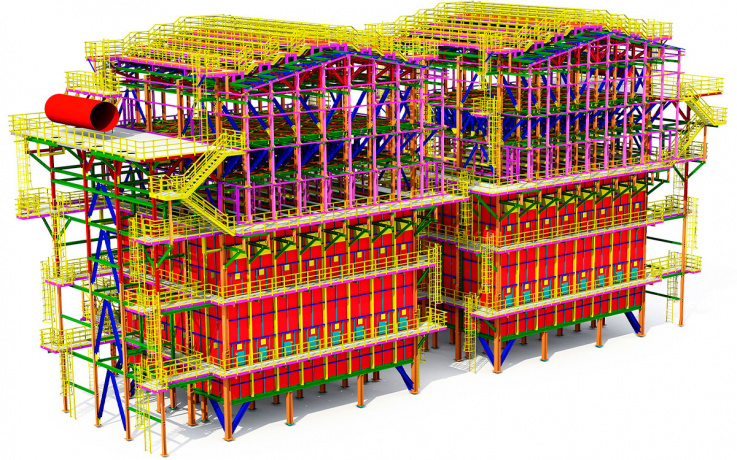

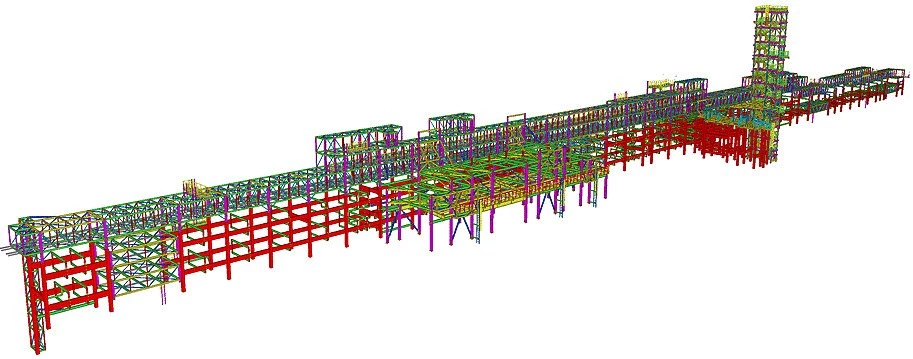

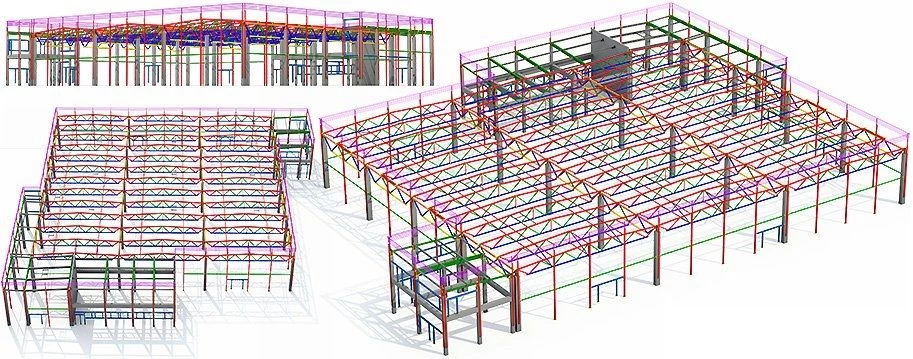

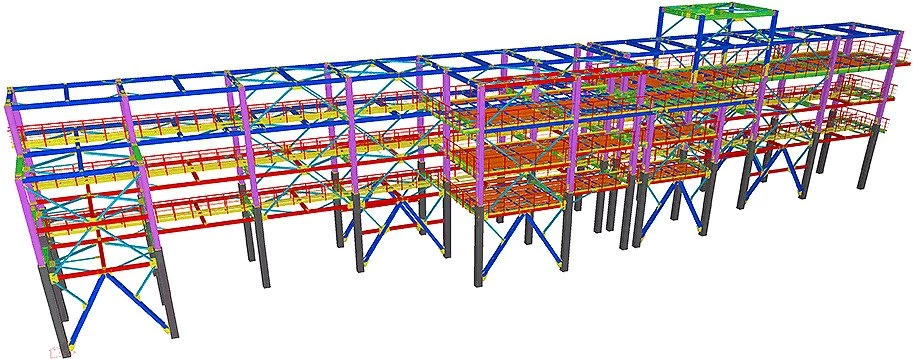

Steel detailing for the public building

Detailing of steel structures is a specialized process for issuing documentation for the manufacture of steel structures at the factory and their installation at site. Often, public buildings have complex architecture, so steel structures are indispensable. This project of the lecture building was developed by the TopEngineer team in 6 months.INFORMATION

| Dimensions | 267 m x 46 m |

|---|---|

| Building height | 27 m |

| Weight | 1 863 765 kg |

| Number of parts | 48 325 |

| Purpose | Public building |

| Documentation | Steel detailing |

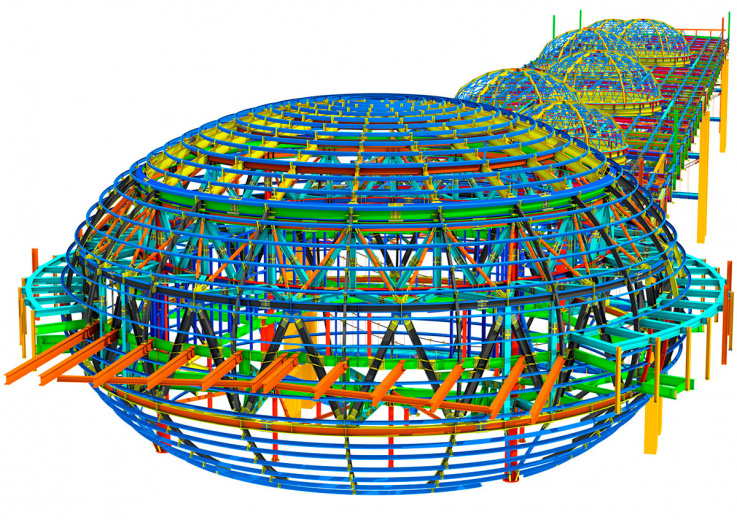

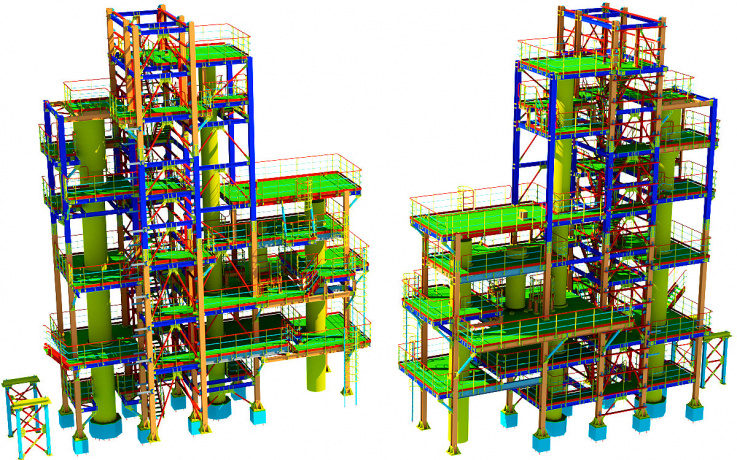

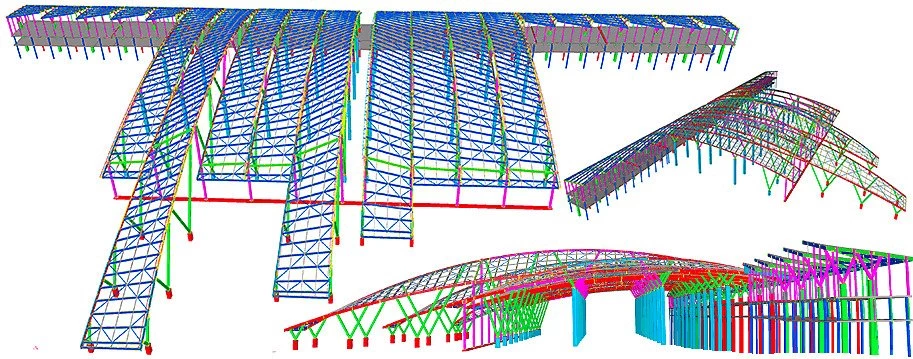

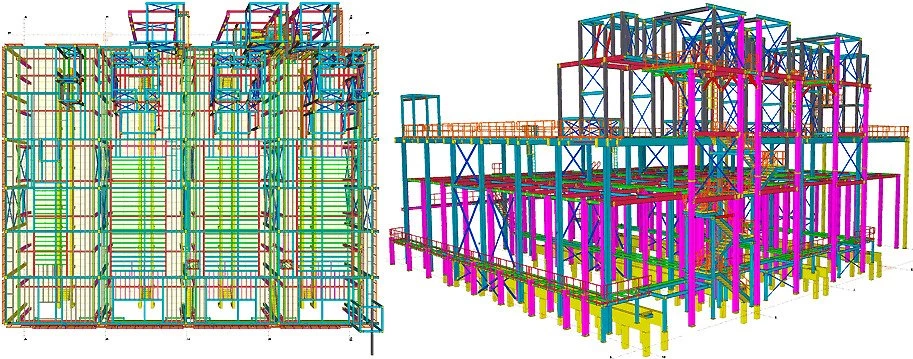

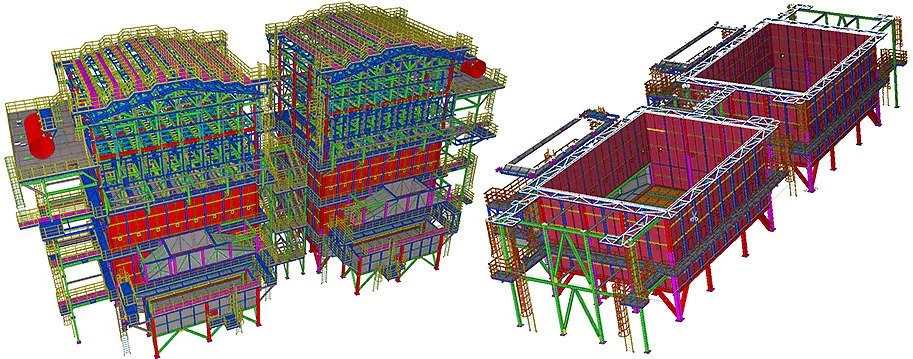

Tekla detailing for reformer furnaces

TopEngineer developed the shop and erection documentation for Steam reformer furnaces. These furnaces are designed to produce hydrogen at manufacture of chemicals such as TDI, MDI, ammonia and methanol. The project was very difficult, but we successfully completed it. The project included two mirror furnaces.INFORMATION

| Dimensions | 58.3 m x 23.5 m |

|---|---|

| Building height | 30 m |

| Weight | 768 000 kg |

| Number of parts | 35 794 |

| Purpose | Reformer furnaces |

| Documentation | Steel detailing |

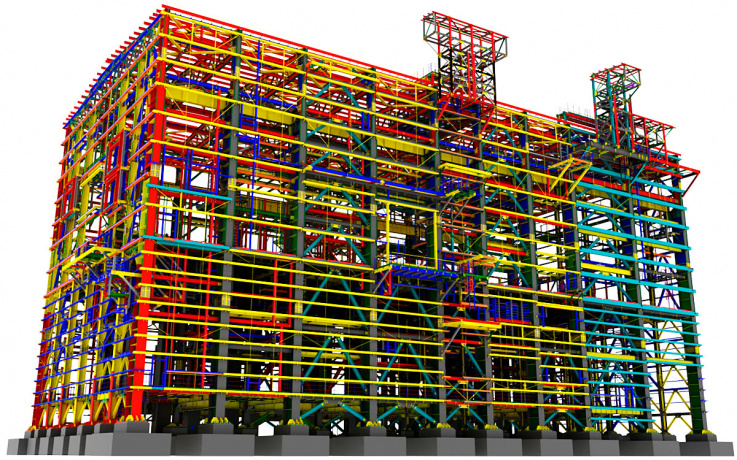

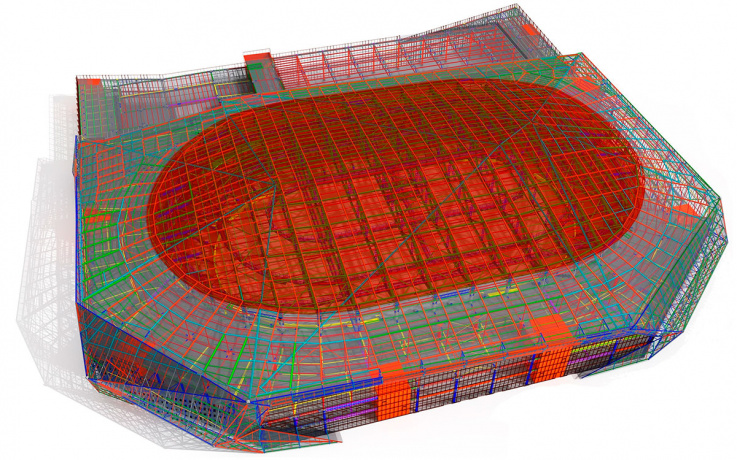

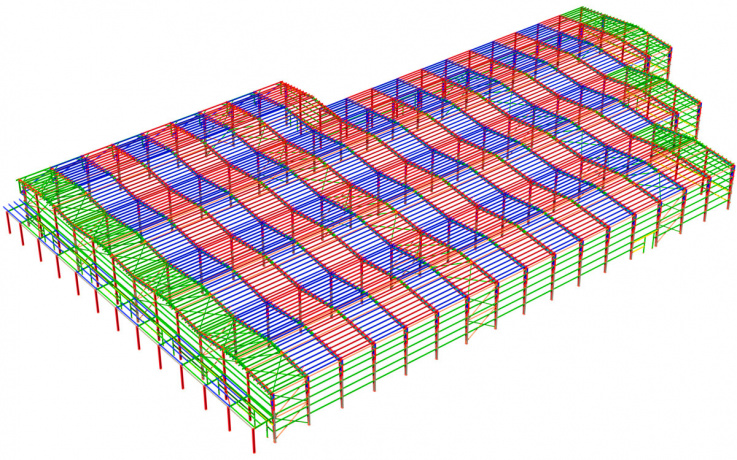

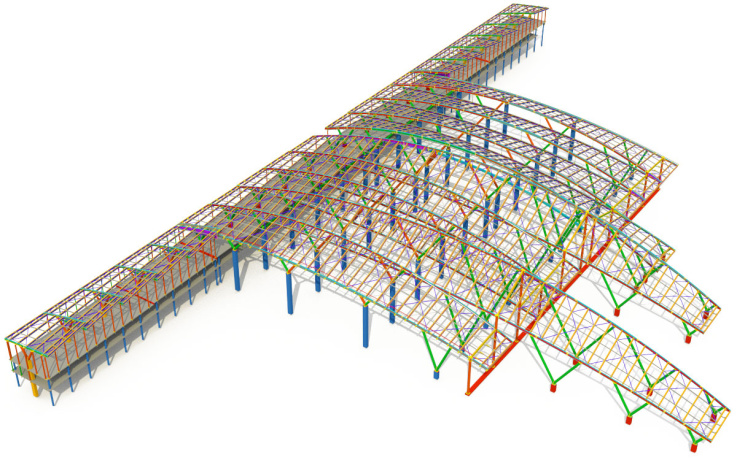

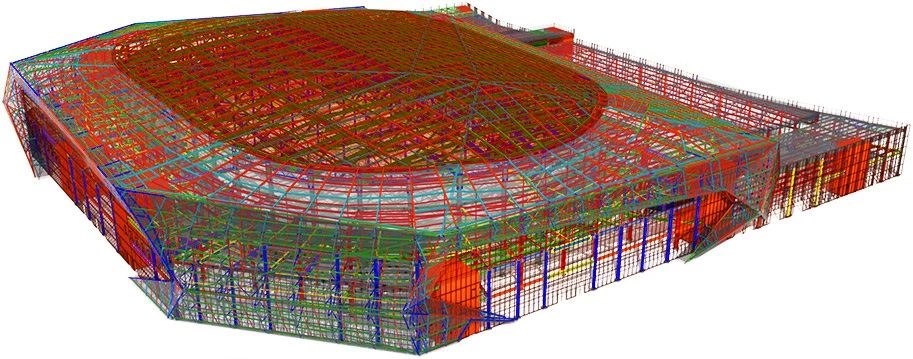

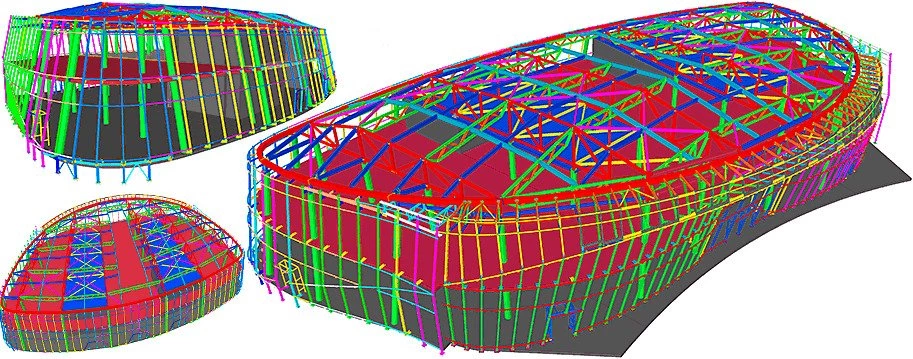

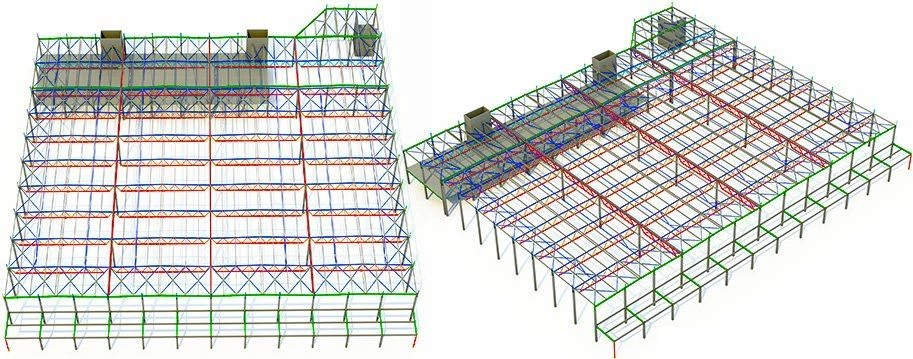

Stadium steel detailing in Tekla

A stadium is a building with a lot of people. Almost always, the roof of stadiums is made of large-span steel structures. For these designs, you need to carefully resemble the production and detailing of steel structures. All welds must be calculated and marked on detail drawings. For this project, in addition to detailing drawings, we calculated and drew installation schemes for large-span truss.INFORMATION

| Dimensions | 165 m x 159 m |

|---|---|

| Building height | 28 m |

| Weight | 4 267 555 kg |

| Number of parts | 112 843 |

| Purpose | Stadium |

| Documentation | Steel detailing |

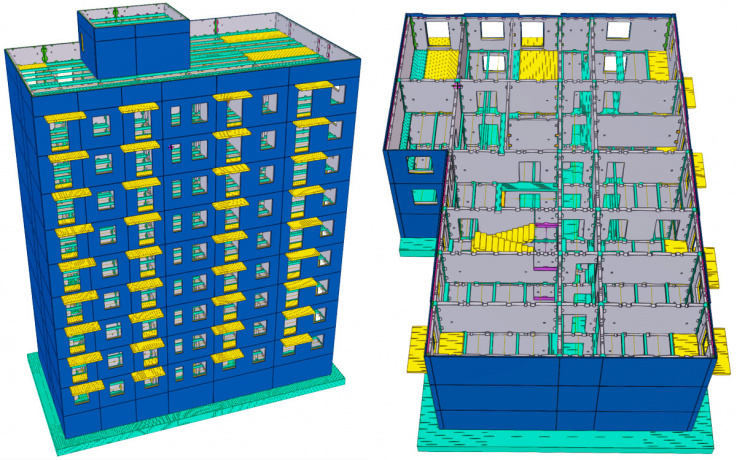

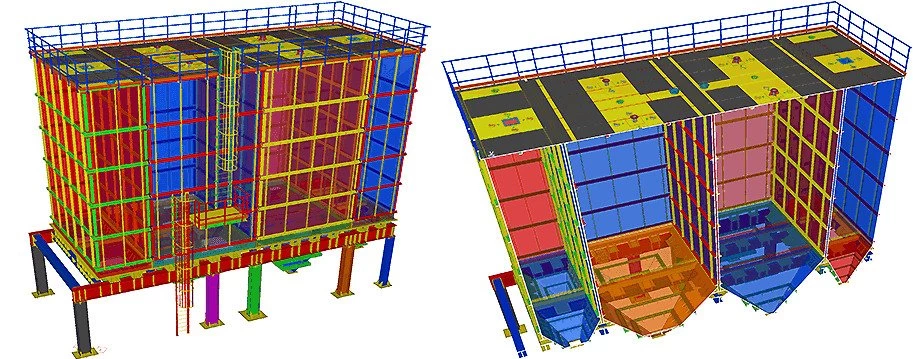

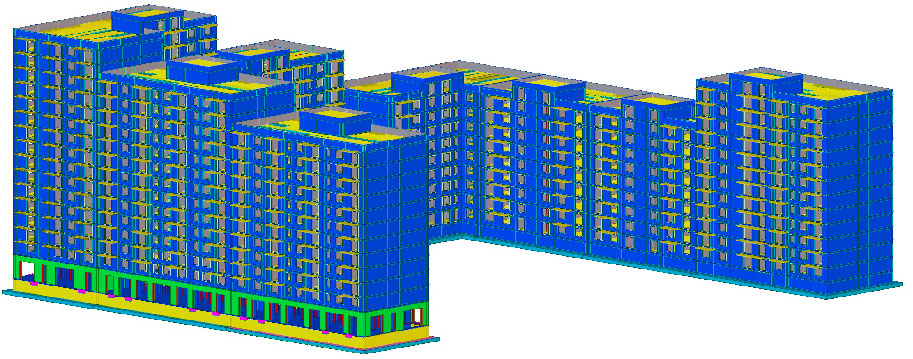

Precast Wall Panel detailing for the residential Building

Precast Wall Panel is the basis of prefabricated panel housing construction. The panels are manufactured at the factory and delivered to the construction site ready-made. Wall panel detailing is one of the most common and frequent industry requirements. The Topengineer has extensive experience in precast detailing. We can consider all the needs of manufacturers. In addition to drawings, we provide erection, assembly drawings, CNC files, embedment detailing, panel fixings, connections, bar bending schedules, etc.INFORMATION

| Dimensions | 84 m x 62 m |

|---|---|

| Building height | 56 m |

| Weight of rebar | 1 680 000 kg |

| Weight of concrete | 99 792 000 kg |

| Number of parts | 154 864 |

| Purpose | Precast wall panels |

| Documentation | Rebar detailing |

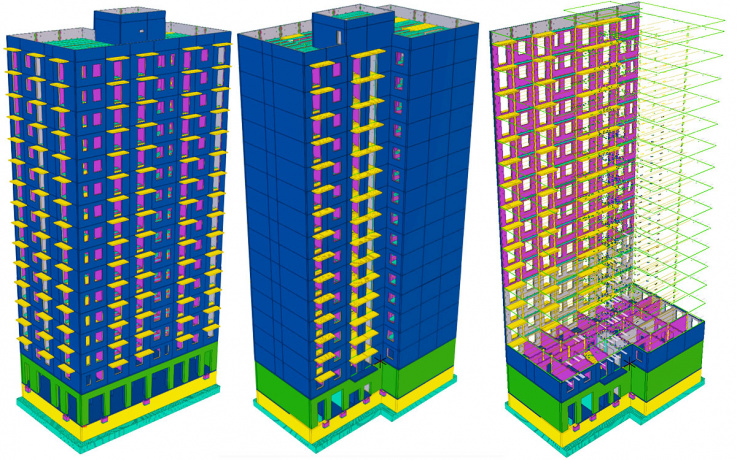

Precast Beam detailing in Tekla Structures

Precast beams are used in prefabricated panel housing construction. Prefabricated beams are cast and curated at the factory. TopEngineer’s team has extensive experience in detailing of precast beams. Detailing of prefabricated beams guarantees accurate dimensions, and therefore eliminates installation errors. Our engineers will perform precast detailing with the highest precision and quality standards, meeting the project deadlines.INFORMATION

| Dimensions | 30 m x 16 m |

|---|---|

| Building height | 36 m |

| Weight of rebar | 840 000 kg |

| Weight of concrete | 2 100 000 kg |

| Number of parts | 13 755 |

| Purpose | Precast beam detailing |

| Documentation | Rebar detailing |

Hollow core slab rebar and formwork detailing

Hollow core slab is an indispensable structural element in construction. Hollow core slab is lightweight and require less concrete in production. Floors and roofs are usually made from these slabs. The Topengineer offers detailing for Hollow core slab in the Tekla Structures. In addition to standard drawings and reports, we can provide control programs for rebar bending machines and formwork installation.INFORMATION

| Dimensions | 29 m x 18 m |

|---|---|

| Building height | 53 m |

| Weight of rebar | 2 400 000 kg |

| Weight of concrete | 14 256 000 kg |

| Number of parts | 48 714 |

| Purpose | Precast Hollow Core Slab detailing |

| Documentation | Rebar detailing |

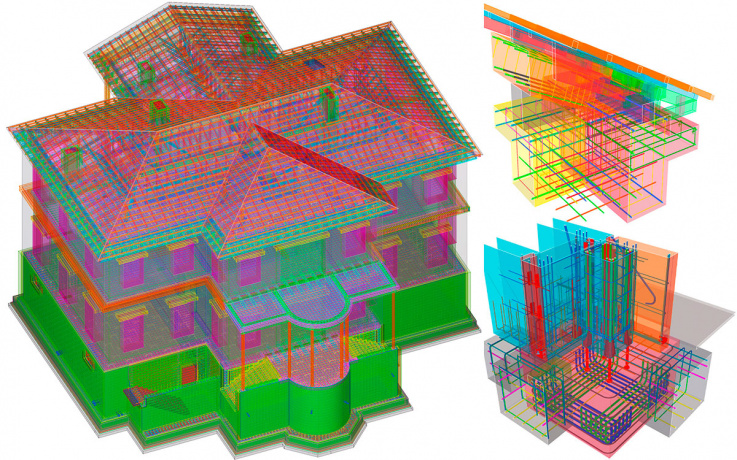

Private house in Tekla structures

We are trusted to perform any kind of rebar detailing by clients around the world, including North America, Canada, Australia, Europe and the Middle East. Topengineer has established itself as a reliable partner for customers around the world. We have completed many detailing, drawing, and modeling projects for clients. We have developed a range of effective solution for the calculation and detailing of reinforced concrete private buildings to help grow your business. Our precast concrete building detailing projects ensure reliability, cost-effectiveness, and schedule.INFORMATION

| Dimensions | 25 m x 26 m |

|---|---|

| Building height | 15 m |

| Weight | 1 967 582 |

| Number of parts | 16 737 |

| Purpose | Private house |

| Documentation | Rebar detailing |

Precast stair detailing in Tekla Structures

All buildings above one floor have stairs. Precast concrete stairs allow you to optimize and rationalize construction processes. Our team has the knowledge and experience to detail prefabricated stairs. Precast detailing can be done for single stair units as well as separate flight and landing. We have a well-established precast factory drawing process and quality assurance procedure.INFORMATION

| Dimensions | 71 m x 54 m |

|---|---|

| Building height | 62 m |

| Weight of rebar | 2 640 000 kg |

| Weight of concrete | 23 760 000 kg |

| Number of parts | 112 320 |

| Purpose | Precast stair detailing |

| Documentation | Rebar detailing |

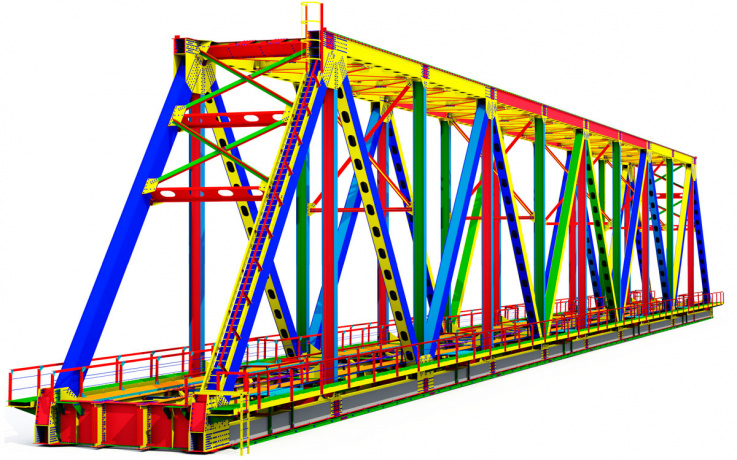

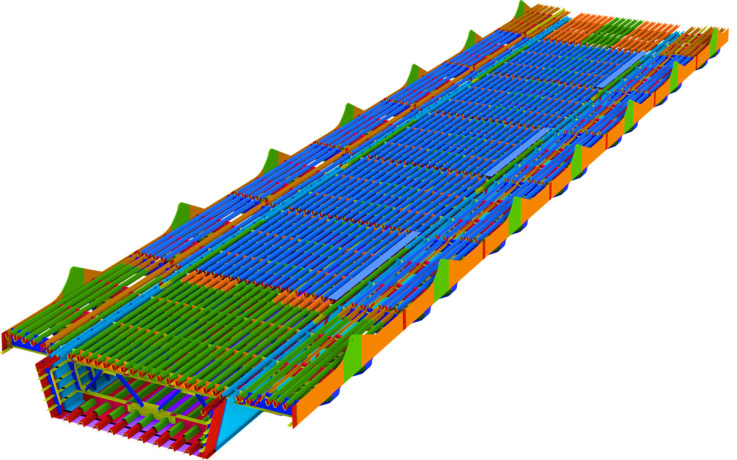

Bridge design services

Topengineer's detailed design process includes the careful elaboration of structural steel and the configuration and calculation of connections. Using Building Information Modeling (BIM), the entire construction process can be integrated into one intelligent information model, resulting in faster construction, higher productivity, lower costs, and improved quality. Topengineer can provide detailing for railroad bridges, long span bridges, drawbridges, segmented concrete bridges, and post-stress bridges.INFORMATION

| Dimensions | 111,2 m x 8,4 m |

|---|---|

| Building height | 16 m |

| Weight | 536 155 kg |

| Number of parts | 11 385 |

| Purpose | Bridge detailing |

| Documentation | Steel detailing |

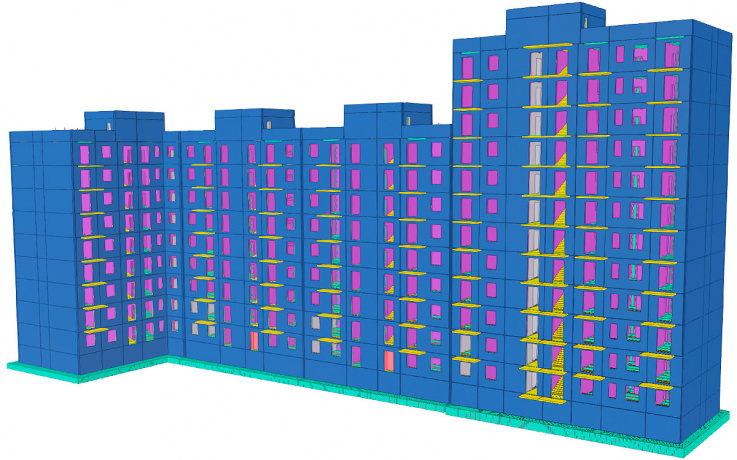

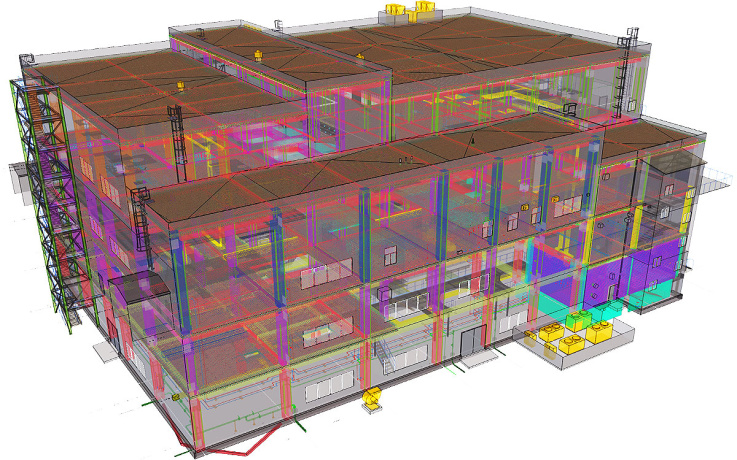

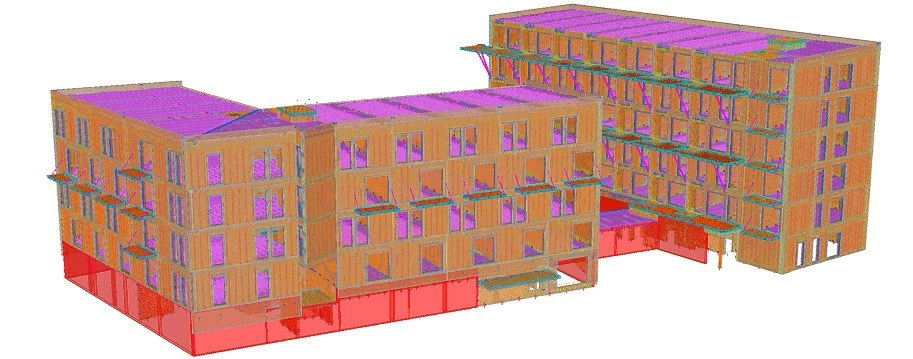

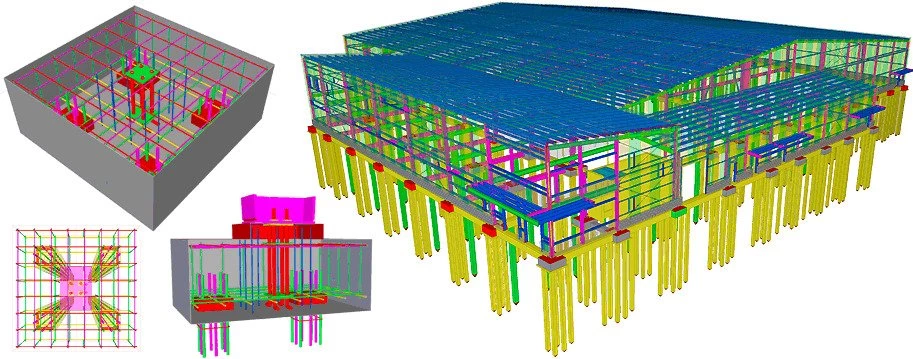

Reinforced Concrete Modeling and Detailing

Topengineer offers the best rebar detailing solutions and rebar services under one roof, for a wide range of buildings and structures. Our experience includes small slabs, stairs and elevators, residential and commercial complexes, bridge structures and sports stadiums. We can offer a dedicated team of reinforced concrete specialists who can detail various types of reinforced concrete structures. All work is carried out under the supervision of certified civil engineers in accordance with any standard (such as AISC, TEMA, ASME, CRSI, ASTM, ACI, BS and IS).INFORMATION

| Dimensions | 87 m x 28 m |

|---|---|

| Building height | 46 m |

| Weight of rebar | 2 200 000 kg |

| Weight of concrete | 20 196 000 kg |

| Number of parts | 542 442 |

| Purpose | Concrete modeling |

| Documentation | Rebar detailing |

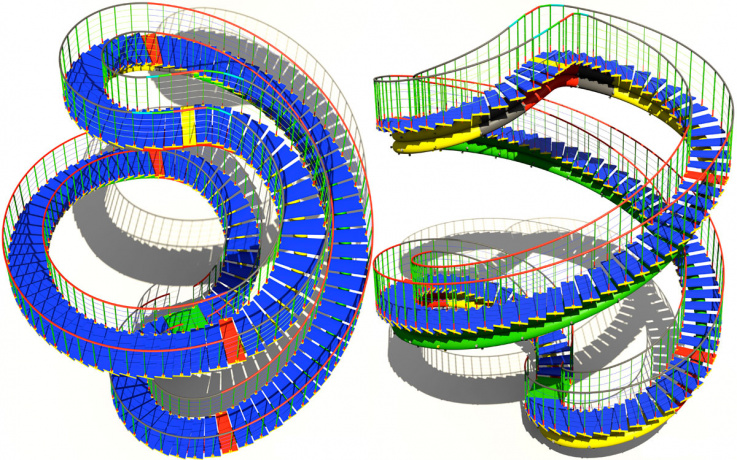

Art spiral stair in Tekla Structures

There are many steels design of stairs such as straight, spiral, curved, U-shaped. In this project we designed spiral stair. Calculation was made using SAP200, drawings and 3D model in Tekla Structural. As regular stairs our project contain main elements such as stringers, supporting beam, dog legs and special pans. Connection of grating to stringer, pan to stringer, stringer to dog leg, stringer to ground was calculated in IdeaStatica.INFORMATION

| Dimensions | 9 m x 9 m |

|---|---|

| Building height | 10 m |

| Weight | 9 378 kg |

| Number of parts | 2 184 |

| Purpose | Art spiral stair |

| Documentation | Steel detailing |

Structural steel detailing for swimming pool

Our scope of work for this project consisted of documentation for steel fabricators, CNC files for machinery, erection plans, and 3D model in Tekla Structures. We delivered super quality steel detailing to steel fabricators, steel erectors and structural engineers for reliable construction. This project was carried out by a team of 8 detailers. Our engineers can make a Tekla Structures models in both metric and imperial systems.INFORMATION

| Dimensions | 102 m x 72 m |

|---|---|

| Building height | 14 m |

| Weight | 586 014kg |

| Number of parts | 35 210 |

| Purpose | Swimming pool |

| Documentation | Steel detailing |

Shelter BIM modeling in tekla structures

TopEngineer create BIM models of any complexity for industrial and civil construction. For this shelter the approach to designing information model involves, the collection information, storage and complex processing of all architectural, design, technological, economic and other information, with all its relationships and dependencies. The Topengineer successfully completed the task of creating a BIM 3D model in Tekla Structures.INFORMATION

| Dimensions | 35 m x 32 m |

|---|---|

| Building height | 40 m |

| Weight | 31 810 |

| Weight of concrete | 14 558 082 kg |

| Number of parts | 27 187 |

| Purpose | Shelter |

| Documentation | Steel detailing |

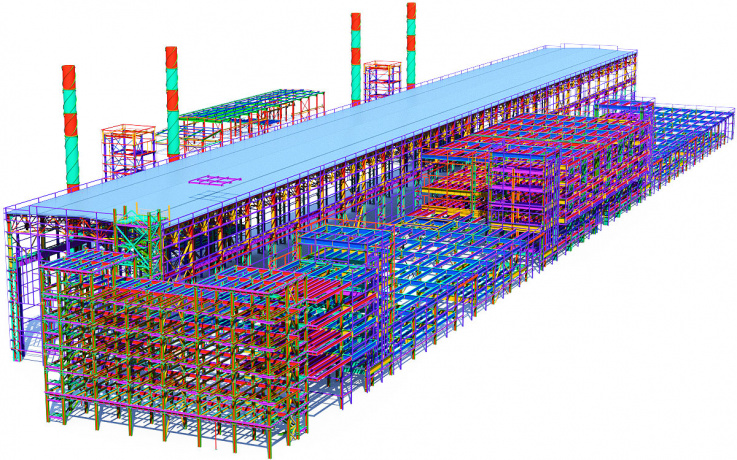

Power plant BIM (Building Information Model) model

Building Information Modelling (BIM) in power plant. Our company has successfully completed a project for the energy sector. The main difficulty in calculating for this plant was a huge amount of equipment and loads from this equipment. With the help of the Grasshopper, we have fully automated the task of applying loads. This project was developed in one Tekla Structures model to reduce errors.INFORMATION

| Dimensions | 344 m x 101 m |

|---|---|

| Building height | 52 m |

| Weight | 8 602 780 kg |

| Number of parts | 198 039 |

| Purpose | Power plant |

| Documentation | Steel detailing |

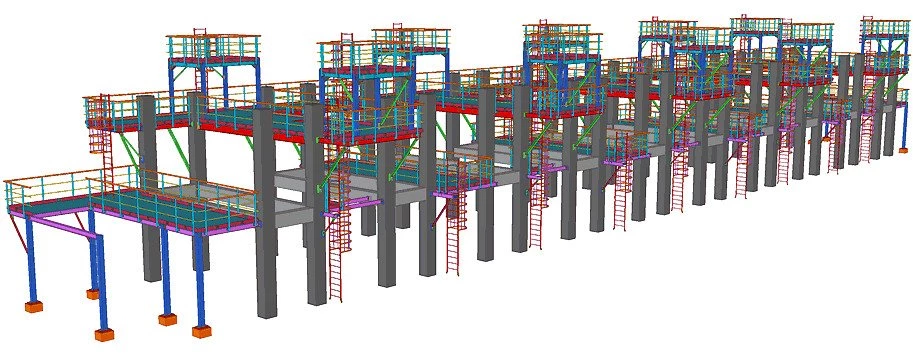

Pipe rack steel detailing in Tekla Structures

Pipe racks are structures for supporting pipes, cables and cable trays. Pipe racks are not buildings, they are mostly open or partially closed. Pipe racks are mainly used in petrochemical, chemical and power plants. Our company TopEngineer has extensive experience in calculating and detailing for Pipe racks. We mainly use International Building Code (IBC) (ICC, 2009), ASCE 7 (ASCE, 2006), AISC 360 (AISC, 2005b) for design. Most structural steel seismic requirements are prescribed in AISC 341 (AISC, 2005a) and AISC 358 (AISC, 2006, 2009)INFORMATION

| Dimensions | 24 m x 18 m |

|---|---|

| Building height | 22 m |

| Weight | 92 123 kg |

| Number of parts | 16 752 |

| Purpose | Pipe rack |

| Documentation | Steel detailing |

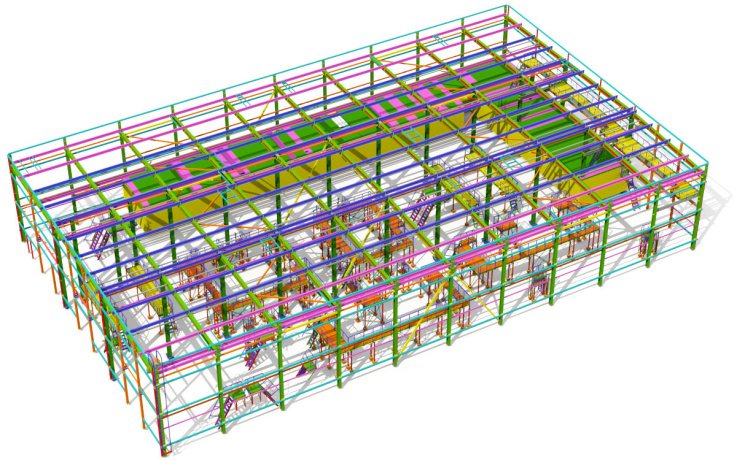

Detailing drawings for Industrial project

TopEngineer works with any steel detailing standards be it Euro Codes or AISC or CISC, we deliver the projects as per our clients’ needs. In addition to 3D model and steel detailing drawings, the project included: BOMs and Material takeoffs, anchor setting plans, shop bolt summary, CNC data for machinery, DXF for plates, cutting drawings for hot-rolled sections.INFORMATION

| Dimensions | 22 m x 8 m |

|---|---|

| Building height | 25 m |

| Weight | 82 200 kg |

| Number of parts | 15 812 |

| Purpose | Shelter |

| Documentation | Steel detailing |

A portal frame with variable cross-sections in Tekla Structures

Approximately 50% of building steel structures in the EU are used in the portal frame of one-story buildings. In such buildings, portal frames are the most common structural form. Portal frames are light and efficient. Steel portal frames provide a highly efficient and economical way of building. In addition, frames provide a larger usable building volume compared to trusses. Steel portal frames are great for transportation. They are relatively flexible, although the deflection of steel portal frames can be reduced, for example, by using larger steel sections or by using more bracings.INFORMATION

| Dimensions | 63 m x 40 m |

|---|---|

| Building height | 10 m |

| Weight | 172 783 kg |

| Number of parts | 7 290 |

| Purpose | Gym |

| Documentation | Steel detailing |

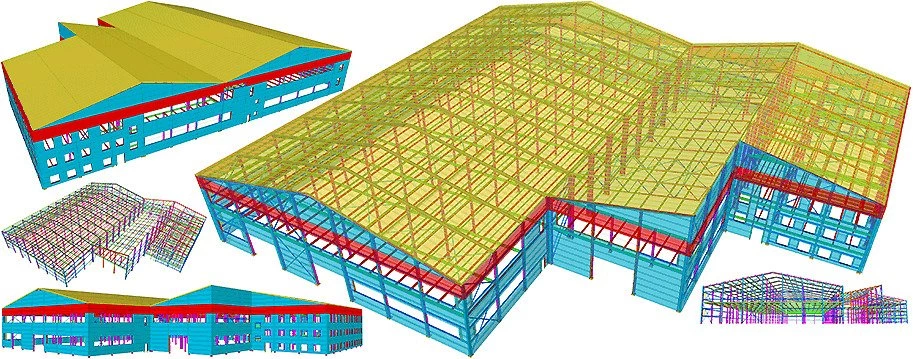

Steel detailing for fitness center in Tekla Structures

For the design of a sports complex to be carried out at a high level, it is necessary that this procedure be carried out by highly qualified designers. Otherwise, the project may have many shortcomings and minor errors. Despite the small size of 76x80 meters, this fitness center is a complex structure, it contains catering, ATMs, auxiliary buildings and areas, conference rooms, rest rooms, etc. To increase inner usable volume, we used portal frame with variable cross section. All structural design was done in Tekla Structures.INFORMATION

| Dimensions | 76 m x 80 m |

|---|---|

| Building height | 38 m |

| Weight | 253 524 kg |

| Number of parts | 14 544 |

| Purpose | Gym with swimming pool |

| Documentation | Steel detailing |

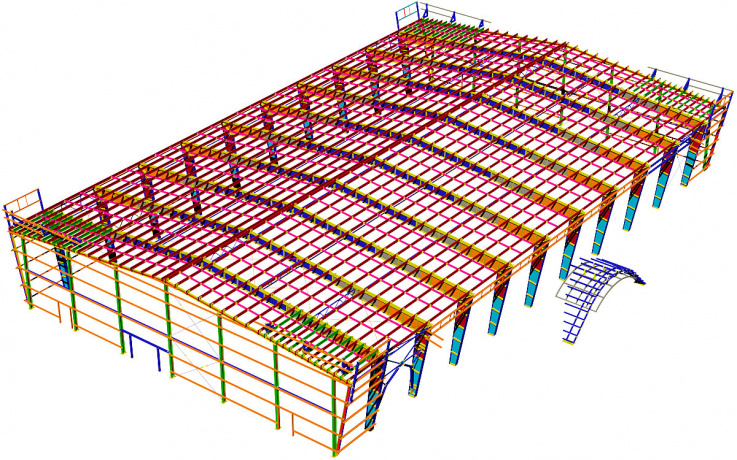

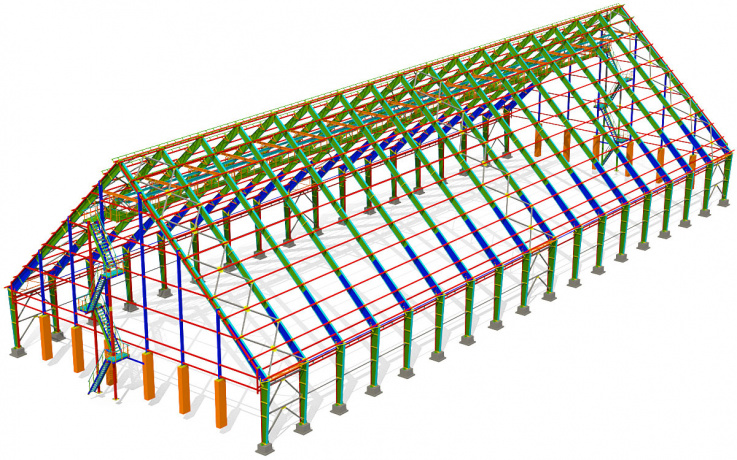

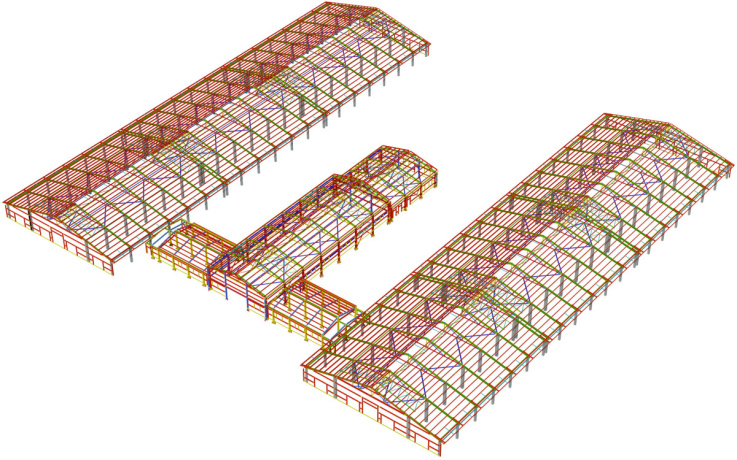

Warehouse design and steel detailing

Our company TopEngineer provides a full range of warehouse design. Our engineers have developed dozens of warehouse projects in various regions of the world. The rich experience gained in the design of warehouses is a guarantee of design quality and has a positive effect on the quality of the developed documentation and is also a guarantee of high-quality manufacturing and installation. This warehouse is designed using portal frame with variable cross section. The steel structure and foundations were made in Tekla Structures.INFORMATION

| Dimensions | 123 m x 72 m |

|---|---|

| Building height | 10 m |

| Weight | 285 351 kg |

| Number of parts | 11 458 |

| Purpose | Warehouse |

| Documentation | Steel detailing |

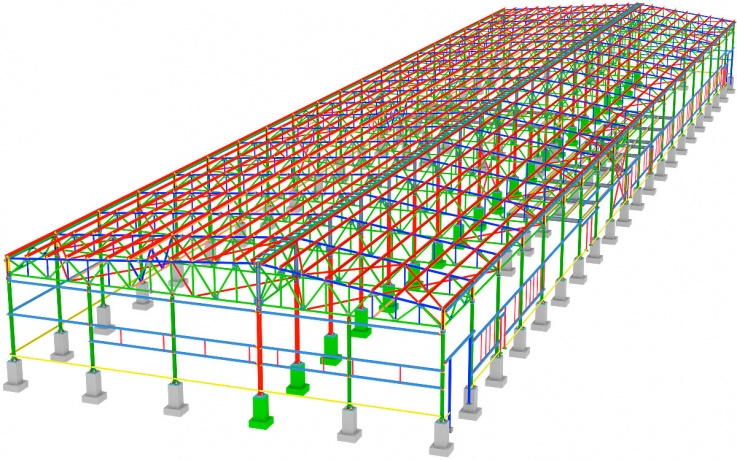

Design and detailing for the production building

Our client asked us to develop a production building with an asymmetric roof. For this project, there were cramped conditions for the foundations. In addition, the client was interested in the smallest possible weight of steel structures. Our company has estimated several options. We have chosen a structure based on trasses. Trusses made it possible to perform symmetrical foundations and made it possible to reduce the weight of structures compared to portal frame with variable cross-section. Calculations were made in the SAP200, 3D model and drawings in the Tekla Structures.INFORMATION

| Dimensions | 120 m x 30 m |

|---|---|

| Building height | 9 m |

| Weight | 208 075 kg |

| Number of parts | 102 214 |

| Purpose | Production building |

| Documentation | Steel detailing |

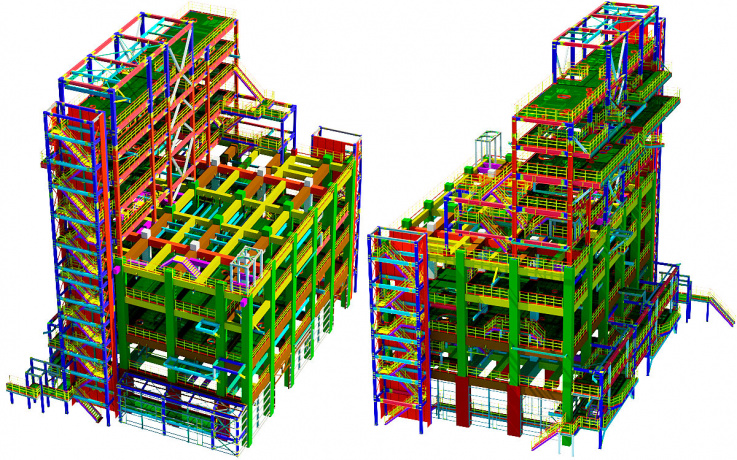

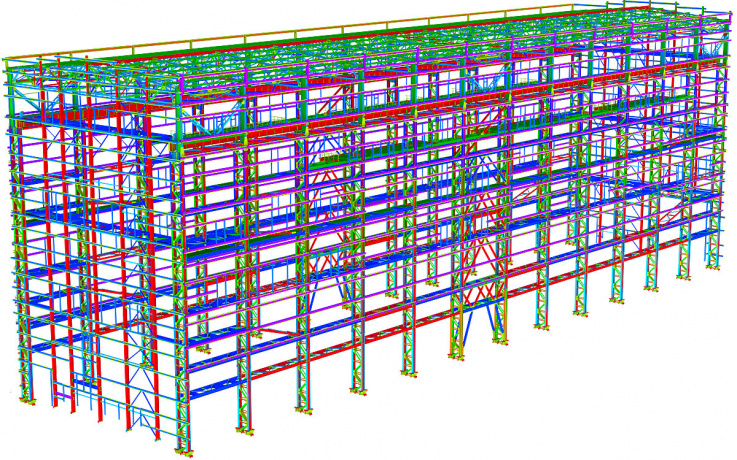

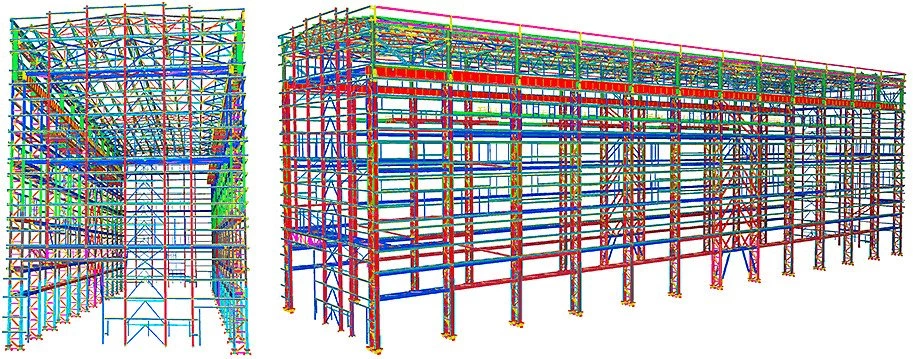

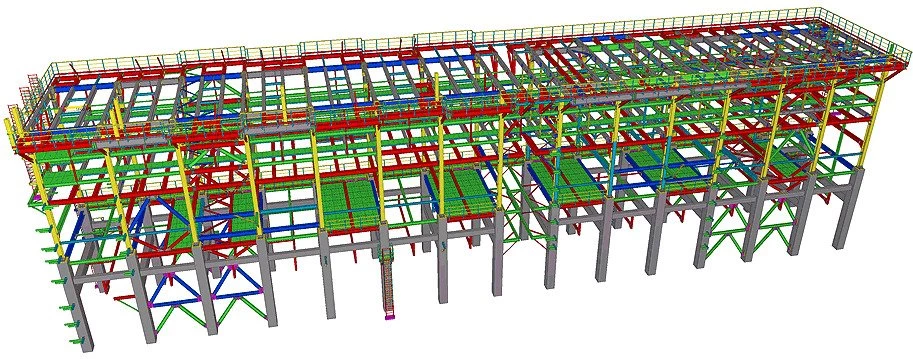

Steel detailing for high rise industrial buildings

This facility is designed to repair ships in the harsh northern regions. The client needed a building in which ships could be dragged for repairs. The gates in the building had to be 20 meters high. Our company TopEngineer successfully completed the project on time. We used lattice structures as columns, which made it possible to reduce the weight of the steel structure. The presence of an overhead crane and a seismological area complicated the design and calculations. The project was completed using Tekla Structures, SAP2000 and ideaStatica programs.INFORMATION

| Dimensions | 102 m x 42 m |

|---|---|

| Building height | 22.5 m |

| Weight | 620 245 kg |

| Number of parts | 13 998 |

| Purpose | Industrial buildings |

| Documentation | Steel detailing |

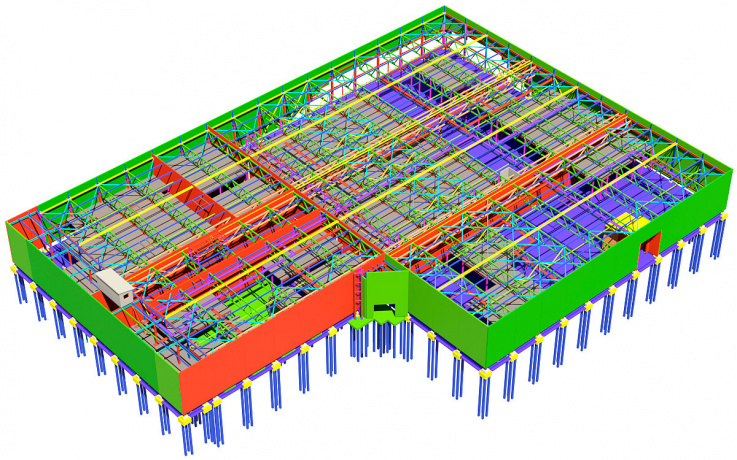

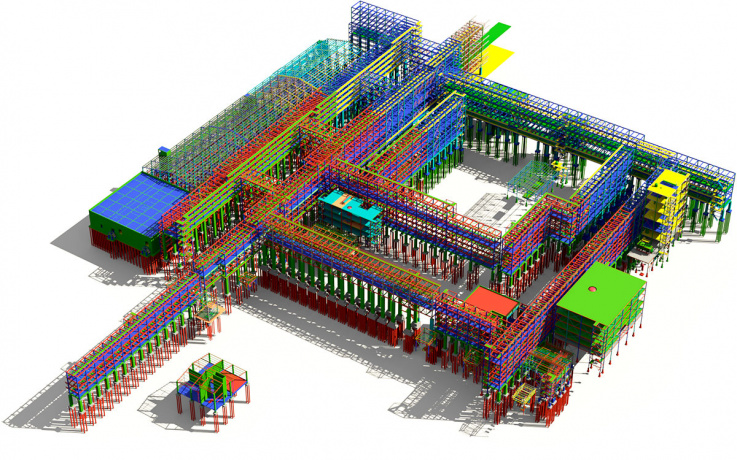

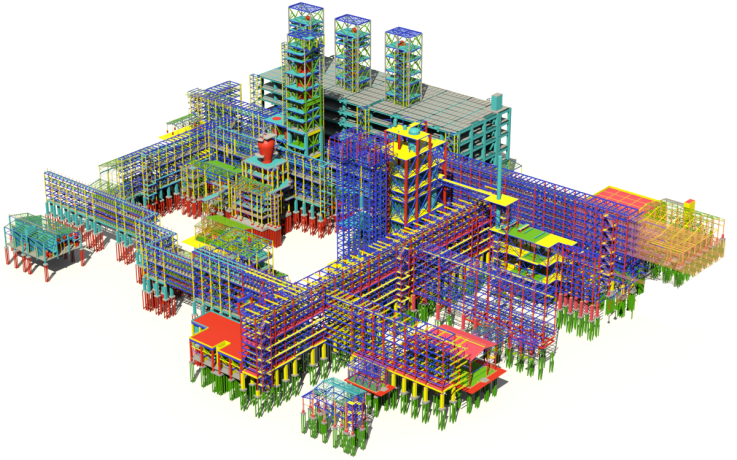

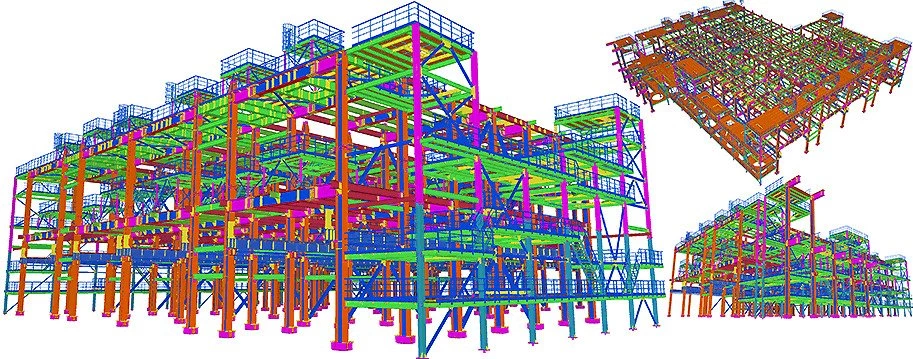

BIM (building information model) for chemical factory in Tekla Structures

On this project, the client was looking for a company that could design a large complex of buildings in BIM. Our company has successfully completed these tasks. According to the 3D equipment model provided by the customer, we calculated all the structures in SAP 2000 and built a detailed 3D model in Tekla Structures. To simplify the design procedure, we have developed an album of typical connections and solutions. To speed up the design, we used Tekla-SAP2000 two-way link. As a result, the customer received a BIM model with equipment and structures.INFORMATION

| Dimensions | 381 m x 275 m |

|---|---|

| Building height | 65 m |

| Weight | 11 275 654 kg |

| Number of parts | 1 651 304 |

| Purpose | Chemical factory |

| Documentation | BIM modeling |

Steel detailing for an agricultural building using Tekla Structures

TopEngineer is a highly experienced company that specializes in environmentally-friendly buildings, particularly in the agricultural sector. We provide comprehensive services from initial design to complete construction, with a strong commitment to outstanding customer care. Our specialist detailing team uses the latest technology to ensure design accuracy, and we work with Tekla Structures to provide a complete package including GA's, fabrication and fitting drawings, and 3D BIM models. Our common agricultural buildings include Barndominiums, Barns, Hay Storage, Horse Stables, Outbuildings, Riding Arenas, Storage Buildings, and Warehouses. With an extensive project list and a commitment to sustainable growth, TopEngineer is dedicated to innovation, knowledge, and driving success in the engineering industry.INFORMATION

| Dimensions | 85 m x 32 m |

|---|---|

| Building height | 22 m |

| Weight | 212 019 |

| Number of parts | 12 911 |

| Purpose | Agricultural building |

| Documentation | Steel detailing |

Bim (building information model) for gas processing factory in tekla structures

Looking to streamline your oil and gas project development? Look no further than BIM technology with TopEngineer. During the planning and design phase, BIM can be used for 3D plant modeling, phase planning, design coordination, and more. And don't forget about existing conditions modeling, which can provide reliable information for informed decision making. In the construction stage, BIM can help with everything from constructability reviews to progress tracking and logistics planning. And in the production, operation, and maintenance phase, asset management, GIS asset tracking, and production management are key. If you're looking for a top-notch BIM company, consider TopEngineer. TopEngineer could make accurate, information-rich 3D models. Whether you're a structural engineer or a contractor, Tekla Structures and TopEngineer is the innovative and unique solution you need.INFORMATION

| Dimensions | 391 m x 273 m |

|---|---|

| Building height | 110 m |

| Weight | 18 131 539 kg |

| Number of parts | 16 173 341 |

| Purpose | Gas processing factory |

| Documentation | BIM modeling |

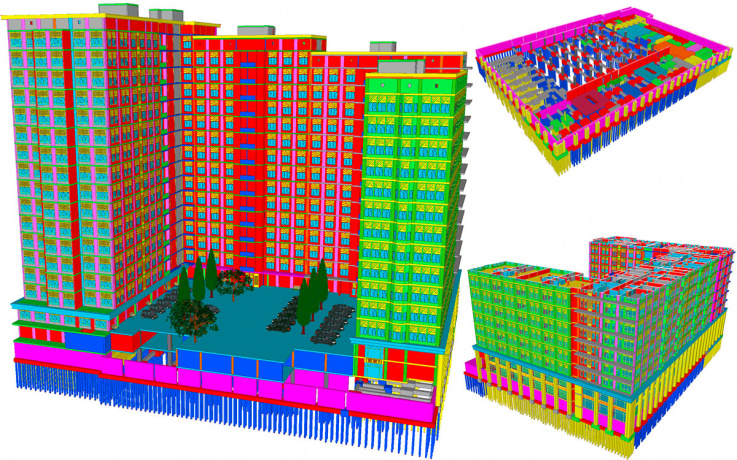

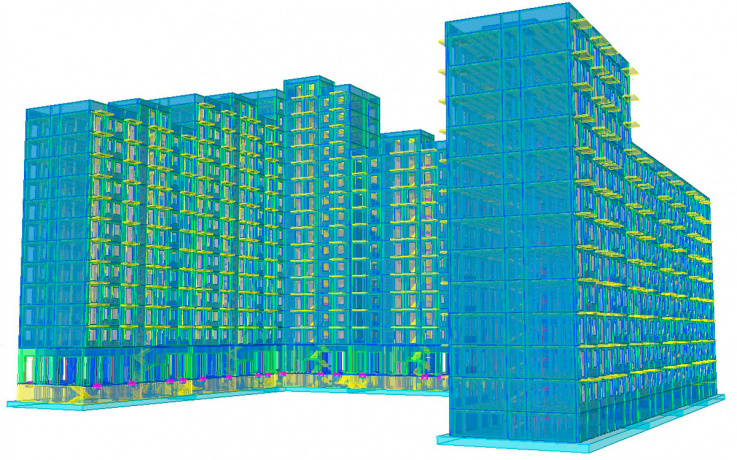

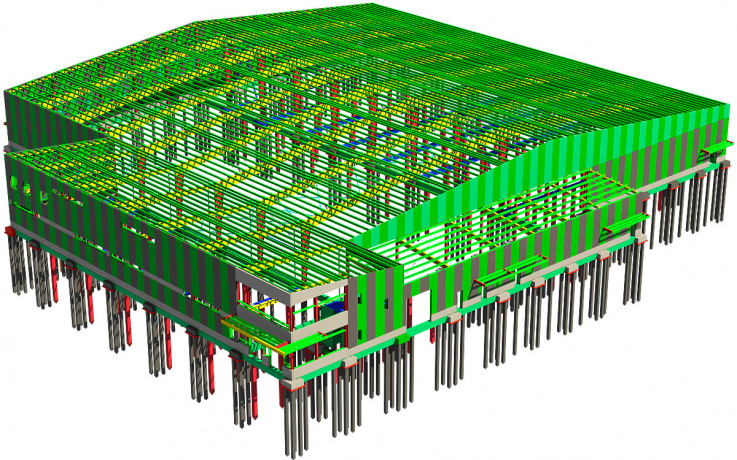

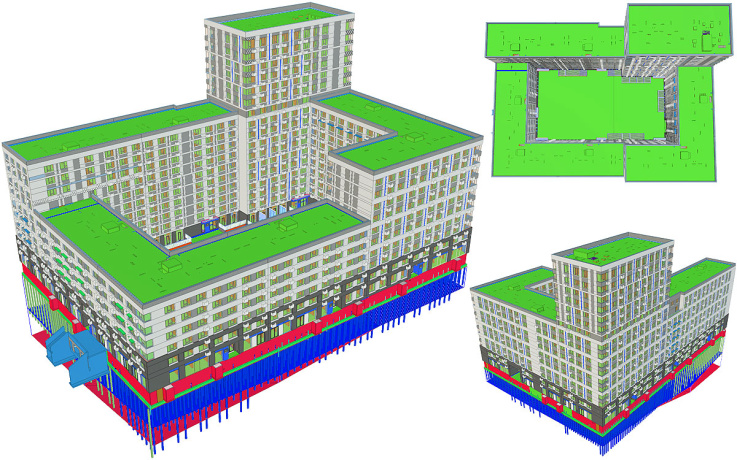

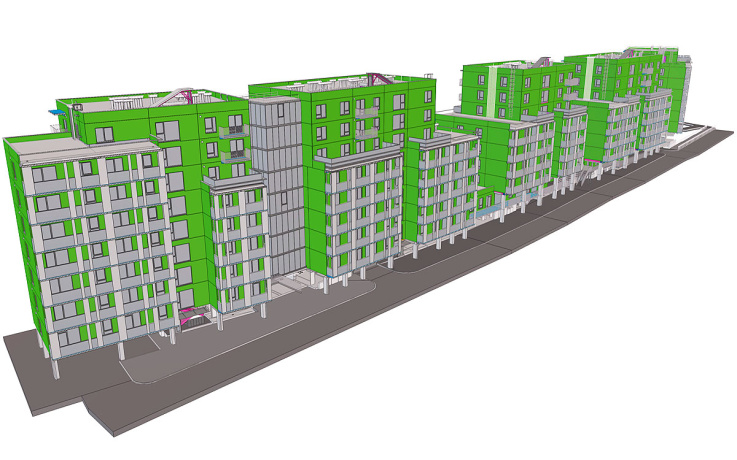

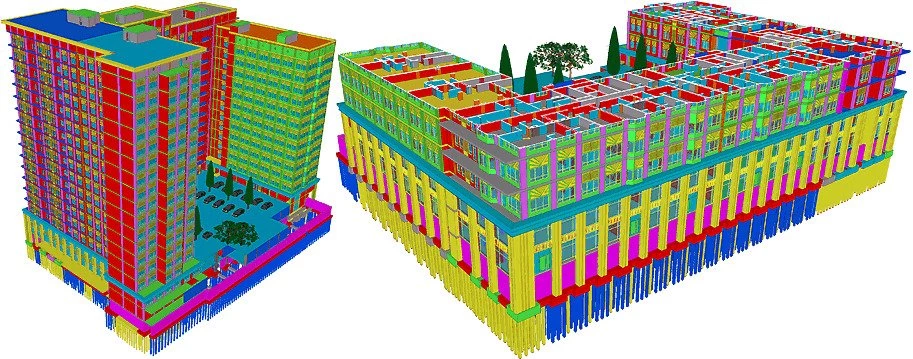

BIM (building information model) for residential complex

Building Information Modeling (BIM) has the potential to benefit residential construction projects of any size by improving productivity, project planning, and building performance. BIM provides developers with greater control over projects from the early stages, allowing for higher levels of detail and timely completion of works. Tekla Structures is a 3D modeling software that enables users to create and manage 3D structural models in concrete or steel. Based on the investigation of several projects, a BIM application value system has been developed to cover all design specialties and ensure constructability. If you choose to work with TopEngineer and adopt BIM, you can effectively address the unique complications of each building sector in residential construction and architecture.INFORMATION

| Dimensions | 90 m x 64 m |

|---|---|

| Building height | 62 m |

| Number of parts | 448 743 |

| Purpose | Residential complex |

| Documentation | Rebar detailing / BIM |

Steel detailing in Tekla Structures for the sewage plant building

TopEngineer offers comprehensive steel detailing solutions using TEKLA STRUCTURES software for industrial building projects. With over a decade of experience, their team of professional civil engineers and designers can create accurate and detailed TEKLA models, generate fabrication and erection drawings, and provide all relevant reports and CNC files. Their services ensure precision and accuracy in manufacturing, leading to seamless project delivery.INFORMATION

| Dimensions | 60 m x 36 m |

|---|---|

| Building height | 11 m |

| Weight | 31 524 kg |

| Number of parts | 11 511 |

| Purpose | Sewage plant |

| Documentation | Steel detailing |

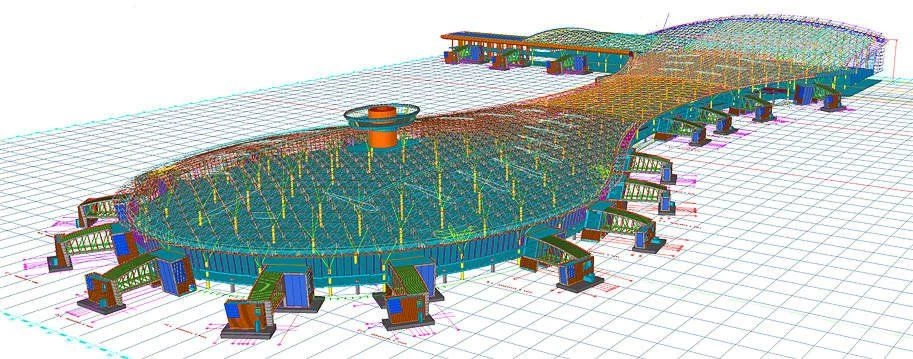

Steel detailing in Tekla Structures for the airport

TopEngineer leverages the power of TEKLA STRUCTURES for efficient and accurate modeling and detailing of complex airport structures. With TEKLA STRUCTURES' ability to process vast amounts of data, we can create detailed 3D and 4D models that streamline the delivery process of design, detailing, fabrication, and construction. The automatic clash checking ensures that costly conflicts are exposed in the model, and the drawings, reports, and CNC data can be automatically created from the 3D model whenever required. This technology enables us to create detailed airport structures that are highly constructable, reducing costly rework and ensuring timely project completion. As a leading steel detailing company, we have the expertise and manpower to handle airport structures of any size, adhering strictly to international industry standards. Let us provide you with technically innovative and practical solutions for your airport projects, delivering superior quality and value for your investment.INFORMATION

| Dimensions | 332 m x 210 m |

|---|---|

| Building height | 31 m |

| Weight | 2 546 123 kg |

| Number of parts | 46 541 |

| Purpose | Airport |

| Documentation | Steel detailing |

Structural drawings for warehouse in Tekla Structures

TopEngineer offers comprehensive steel detailing solutions using TEKLA STRUCTURES for warehouses and other industrial buildings. Our team has the technical expertise and experience to handle 5,000 tons of steel per month and strictly adheres to international industry standards. Our design solutions include a wide range of options such as universal beams or columns, box section, lightweight C or Z section, and open web trusses. We consider important design considerations such as storage space, loading docks, parking, and worker facilities. Our performance floors are designed for maximum productivity and longevity, with detailed joint and structural designs. Trust TopEngineer to provide innovative and cost-effective warehouse solutions with accurate structural drawings.INFORMATION

| Dimensions | 121 m x 114 m |

|---|---|

| Building height | 8 m |

| Weight | 609 102 kg |

| Number of parts | 34 848 |

| Purpose | Warehouse |

| Documentation | Structural drawings |

BIM model for production building in Tekla Structures

Looking for fast and accurate engineering services? Look no further than TopEngineer! With experience in both the USA and European market, we offer TEKLA and BIM modeling, detailing, drawings, calculation, optimization, and design for various structures. BIM technology provides precise virtual models for better analysis and control. With Tekla software, you can create constructible models for efficient workflows. Plus, BIM allows manufacturing owners to acquire complete 3D models of facilities for streamlined production planning and identifying problems earlier. Choose TopEngineer for all your engineering needs and experience the difference today!INFORMATION

| Dimensions | 65 m x 57 m |

|---|---|

| Building height | 27 m |

| Number of parts | 75 250 |

| Purpose | BIM model |

| Documentation | Structural drawings |

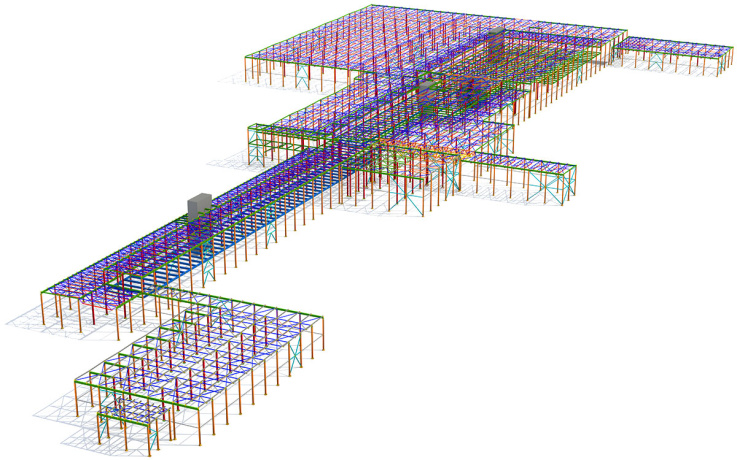

Structural detailing services using Tekla Structures

Our experienced team of experts utilizes the latest TEKLA STRUCTURES software to provide you with the most accurate and detailed steel drawings, framing plans, and miscellaneous steel designs. We have the manpower and technical expertise to handle even the largest projects, and our strict adherence to international industry standards ensures that our work is of impeccable quality. We work closely with owners, architects, and engineers to help address any concerns that may arise throughout the construction process, from potential engineering issues to redesigns and beyond.So why settle for less when you can have the best? Contact Topengineer today and experience the difference for yourself!

INFORMATION

| Dimensions | 414 m x 175 x |

|---|---|

| Building height | 14 m |

| Weight | 2 246 506 kg |

| Number of parts | 61 710 |

| Purpose | Factory |

| Documentation | Steel detailing |

Steel fabrication detailing in Tekla Structures

Our shop drawings cover everything from preparation to onsite delivery, including specifications on standards, fabrication purposes, and steel grades. These drawings are essential for establishing benchmarks that meet your specific design requirements, avoiding conflicts and ensuring that everyone is on the same page. Erection drawings provide a communication channel between structural engineers, steel fabricators, and contractors, showing specific information and requirements for work on the job site. These drawings provide everything from the position of each component in the building to installation instructions and more. Say goodbye to the headache of steel fabrication with TopEngineer and TEKLA STRUCTURES, which offers detailed GA and fabrication drawings. Our expert steel detailers interpret architectural and structural engineering drawings, so you'll know exactly what you're working with.INFORMATION

| Dimensions | 102 m x 24 m |

|---|---|

| Building height | 8.5 m |

| Weight | 244 231 kg |

| Number of parts | 25 973 |

| Purpose | Production building |

| Documentation | Steel detailing |

Rebar design and detailing services

TopEngineer and TEKLA STRUCTURES offers a one-stop solution for all your rebar design and detailing needs. Our experienced engineering professionals provide a cost-effective solution for detailed engineering of RCC and PT elements, including preparation of fabrication/shop drawings, detailing of pre-cast structures and post-tensioned elements. We also provide fast and accurate estimation for bid documents, ensuring compliance with detailing standards, and can provide accurate and detailed reinforcement steel placement drawings and BBS for a wide range of projects across the globe. With a fast turn-around time and pricing based on your needs, TopEngineer and TEKLA STRUCTURES makes rebar design and detailing a breeze.INFORMATION

| Dimensions | 0 |

|---|---|

| Building height | 0 |

| Weight | 0 |

| Purpose | Residential building |

| Documentation | Rebar detailing |

Bridge BIM modeling in Tekla Structures

Exciting news in the bridge industry! TopEngineer is leading the way in defining a new national data standard for BIM in the US and Europe, enabling efficient data sharing between designers and contractors. This not only allows for more automation during construction, better asset management, and reliable data exchange, but also offers a complete 3D electronic model for efficient and effective management throughout the delivery stages. And, with the use of TEKLA STRUCTURES, an all-encompassing digital solution can be developed to support parametric 3D modeling activities and information processing, integration, and management within the context of Italian regulations. BIM is changing the game for the bridge industry!INFORMATION

| Dimensions | 220 m x 38 m |

|---|---|

| Building height | 30 m |

| Weight | 786 780 kg |

| Number of parts | 75 769 |

| Purpose | 0 |

| Documentation | Steel detailing |

We will call you back

It is easy to order training courses, just leave your phone number and our consultant will call you back.