ABOUT US

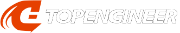

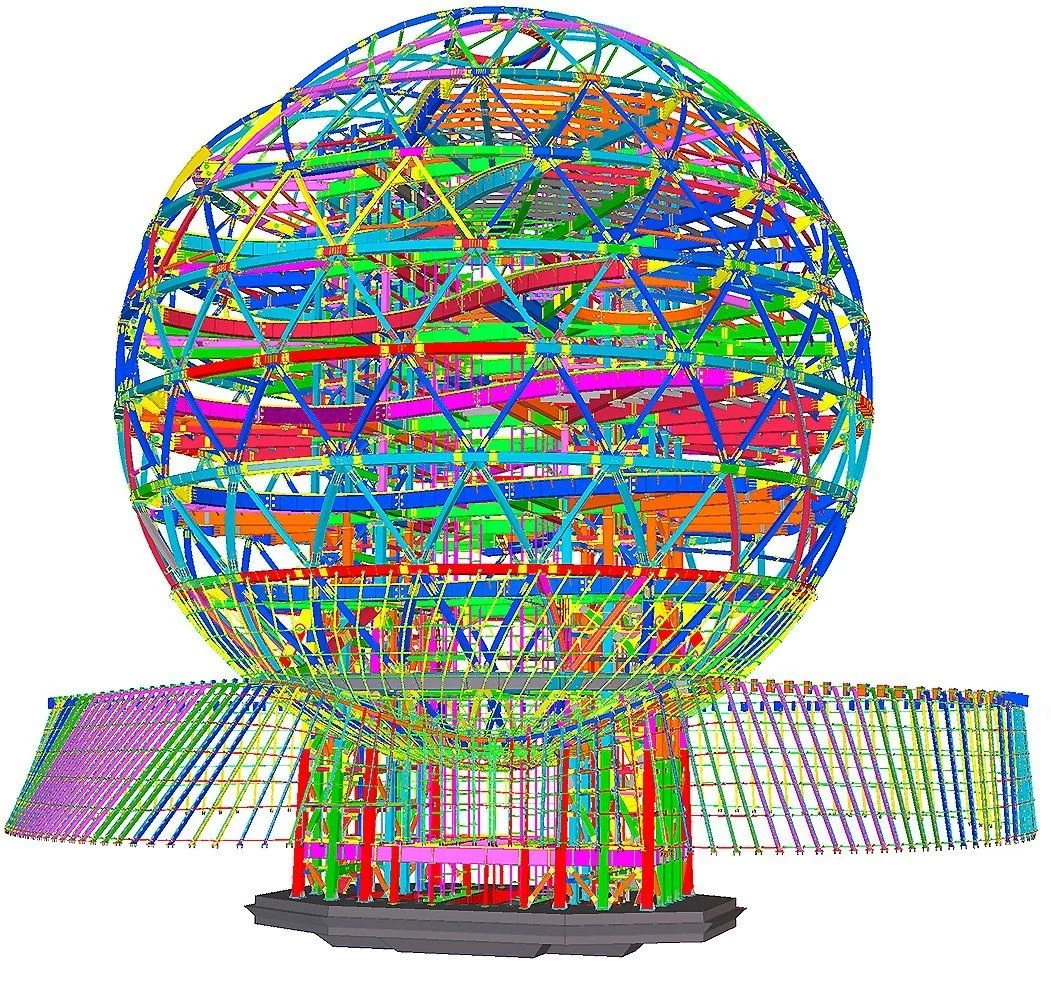

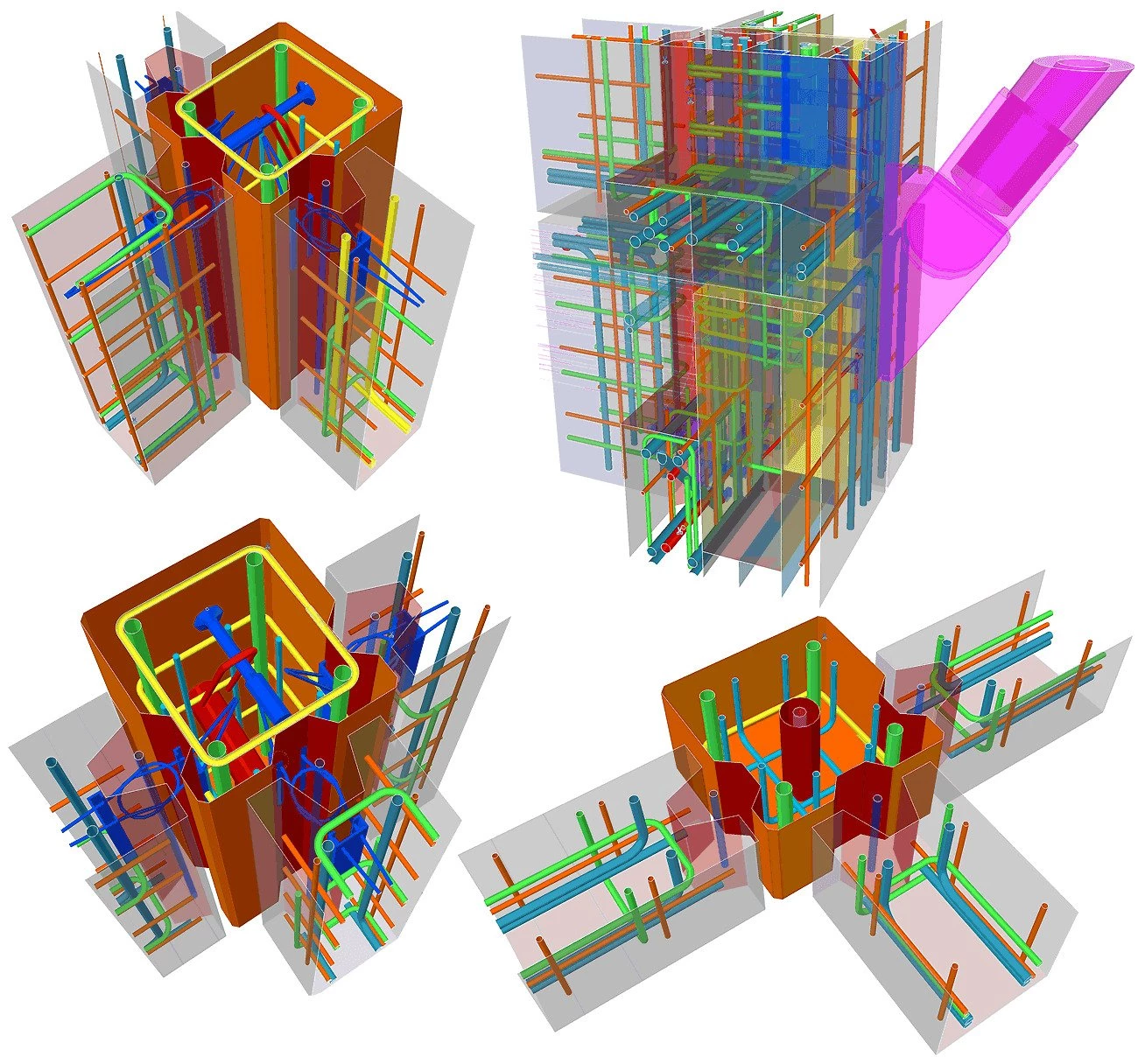

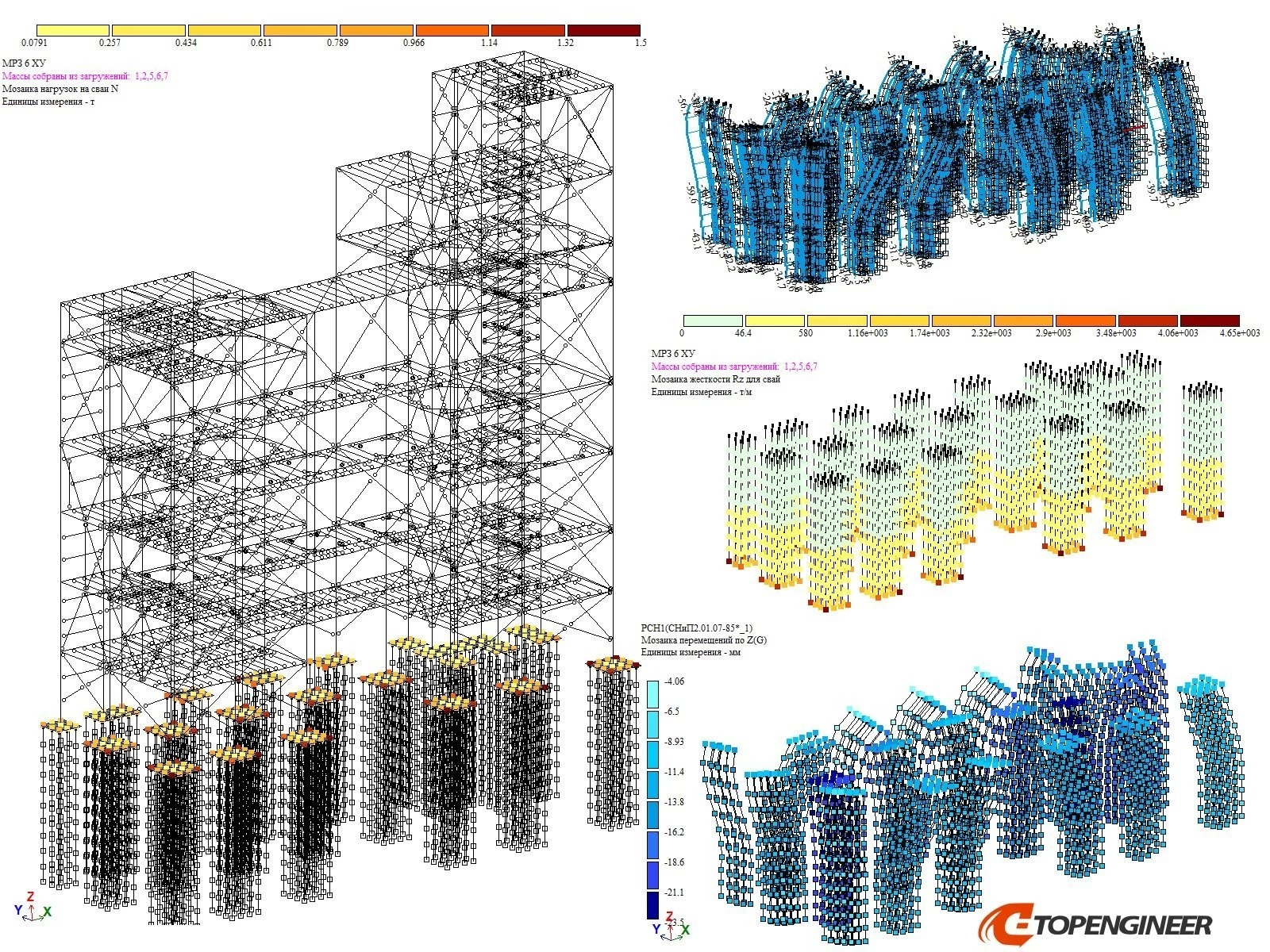

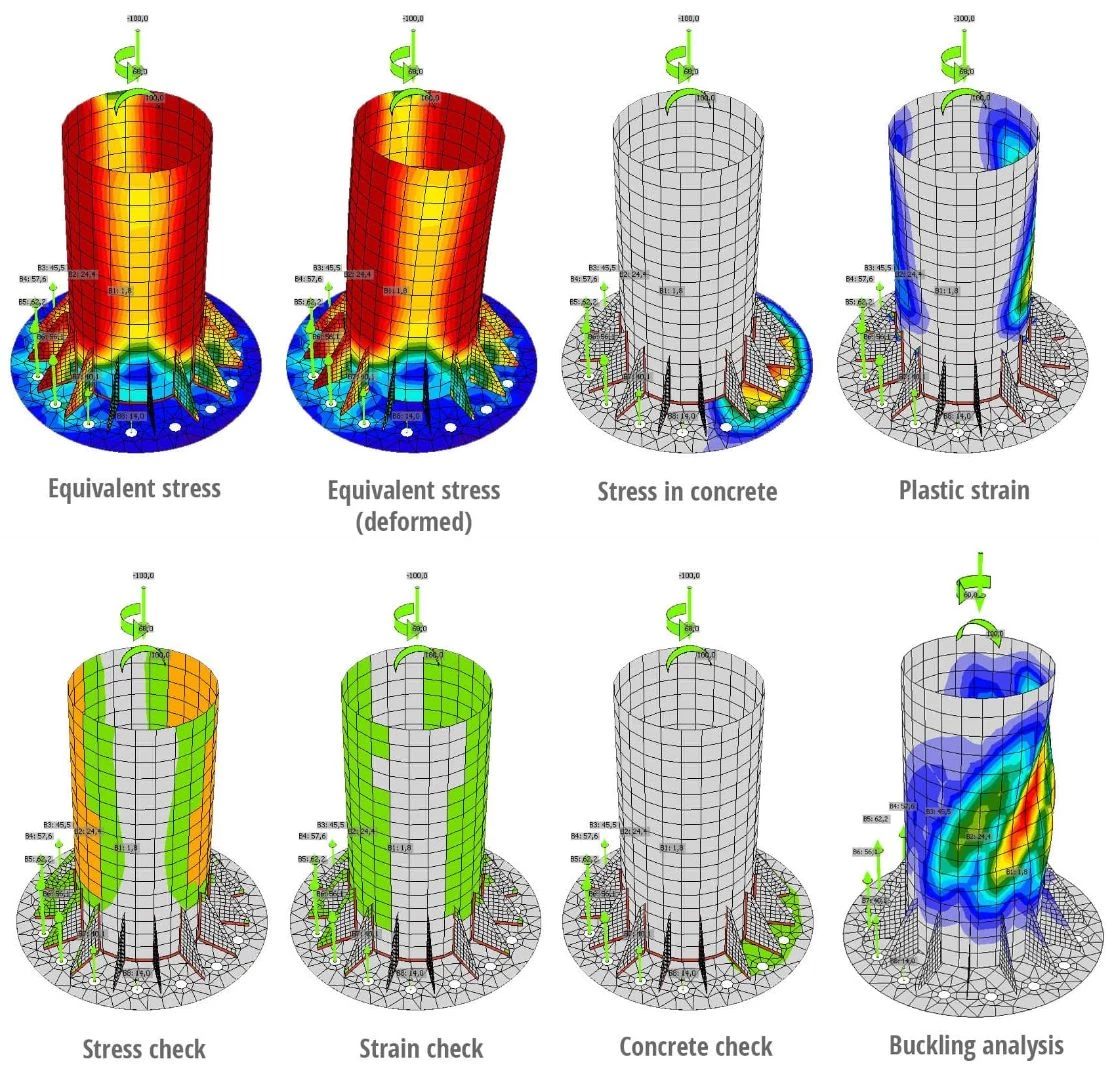

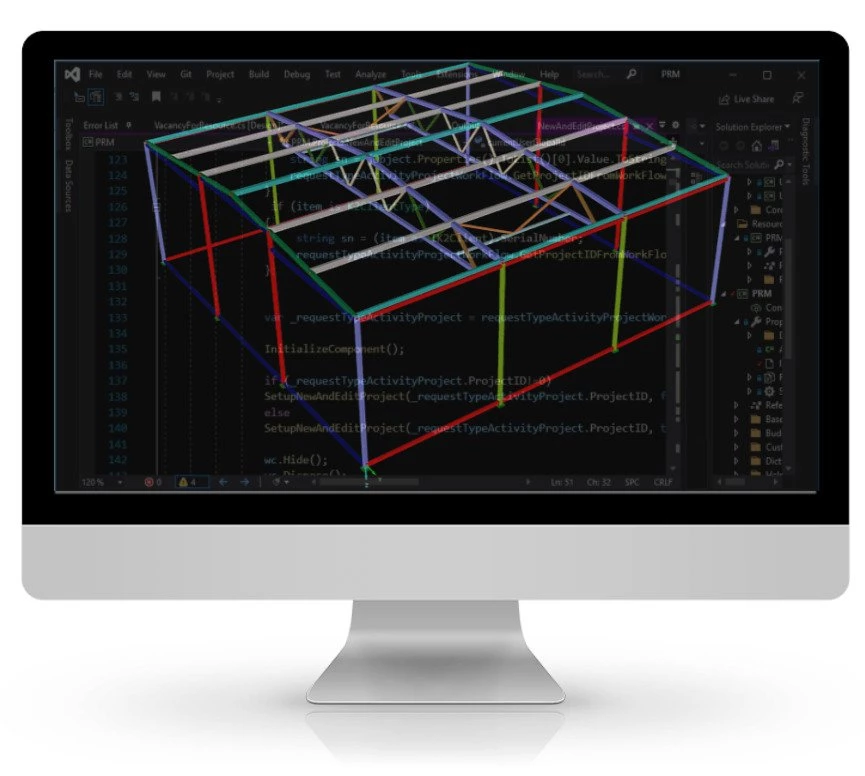

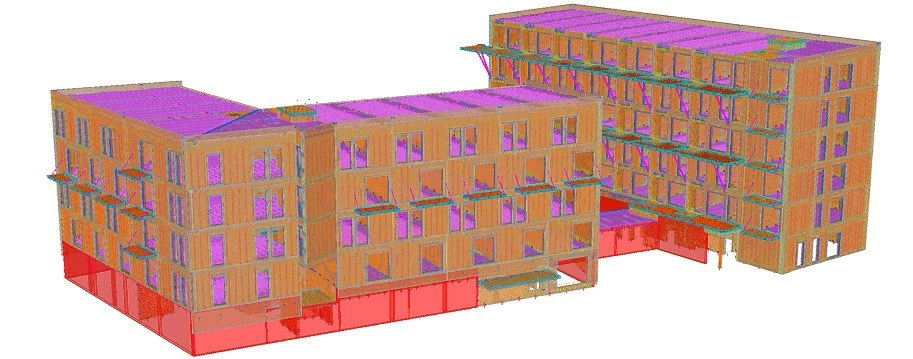

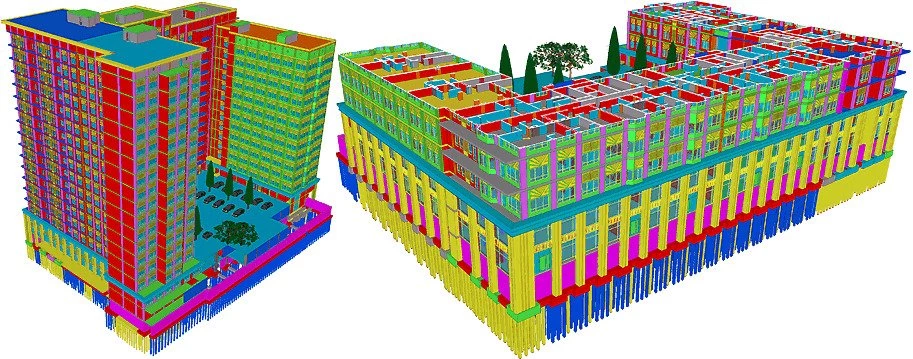

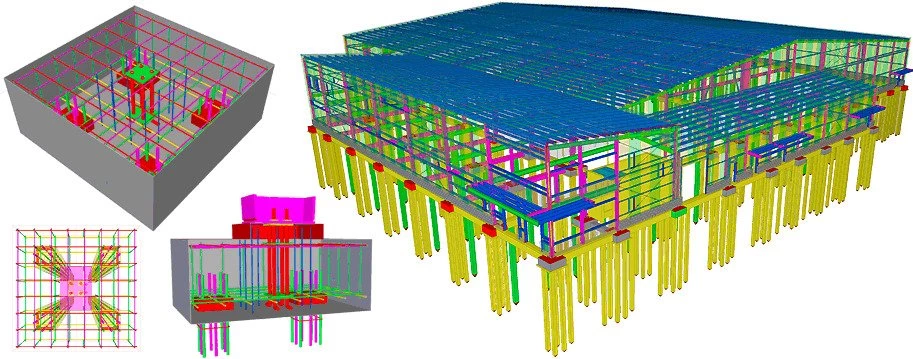

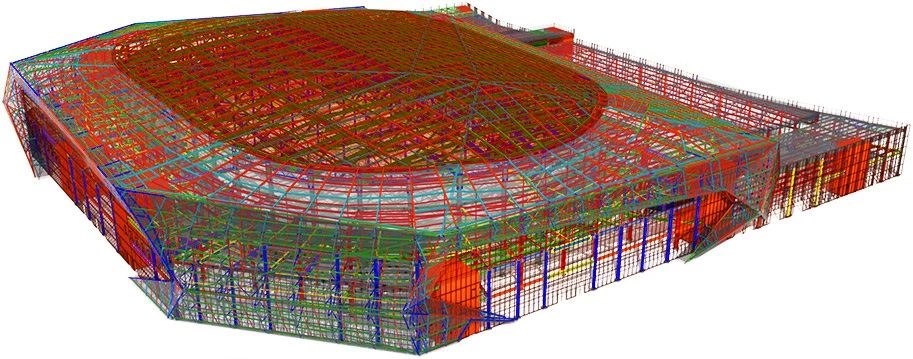

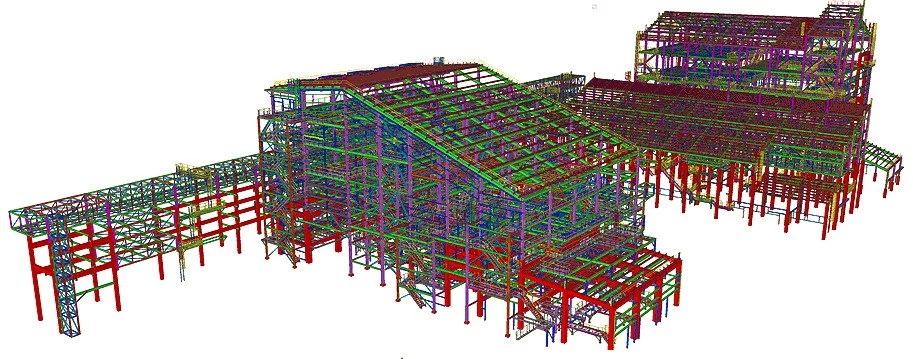

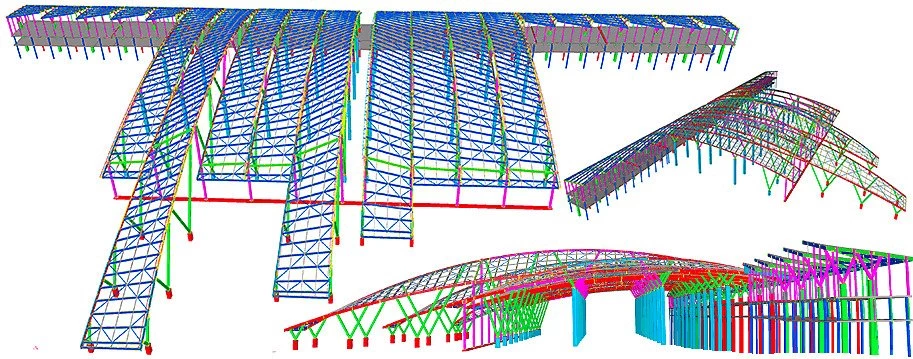

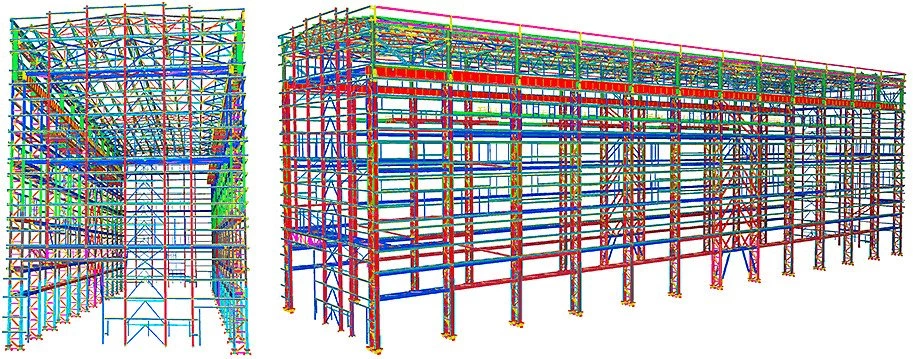

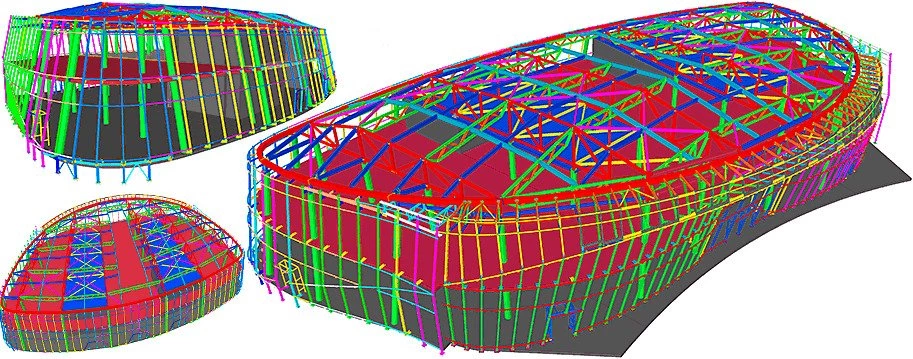

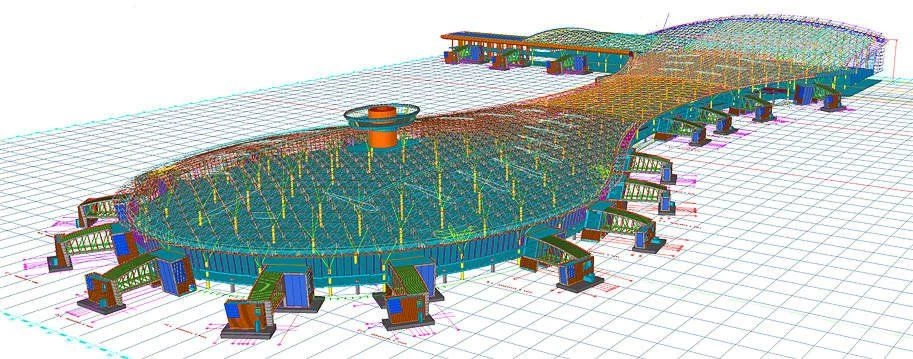

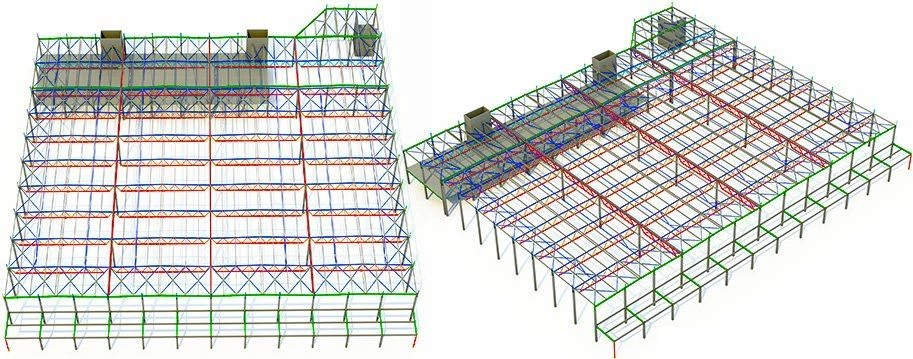

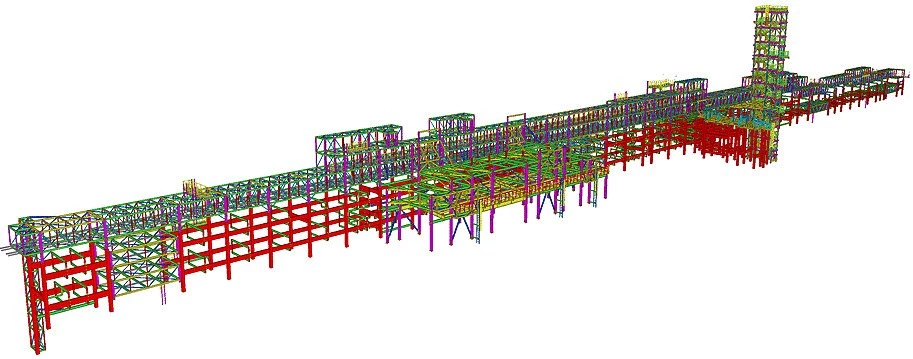

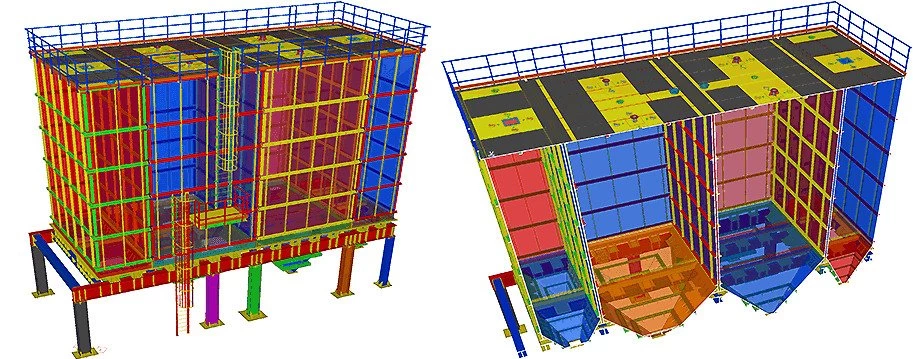

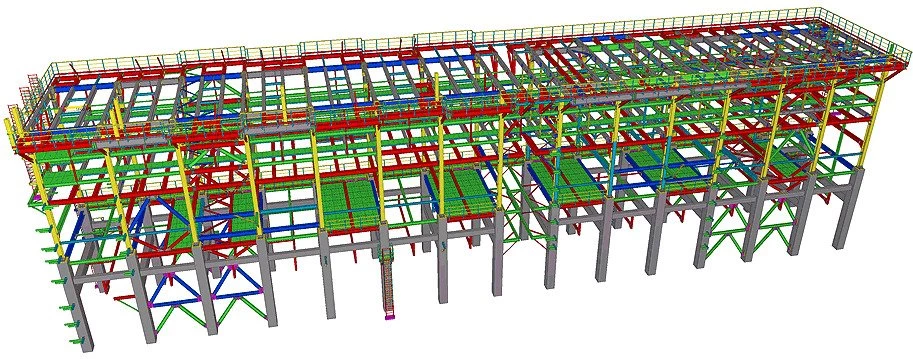

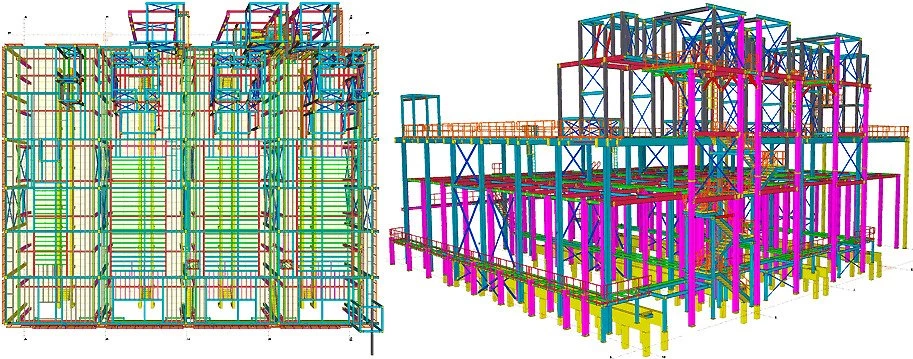

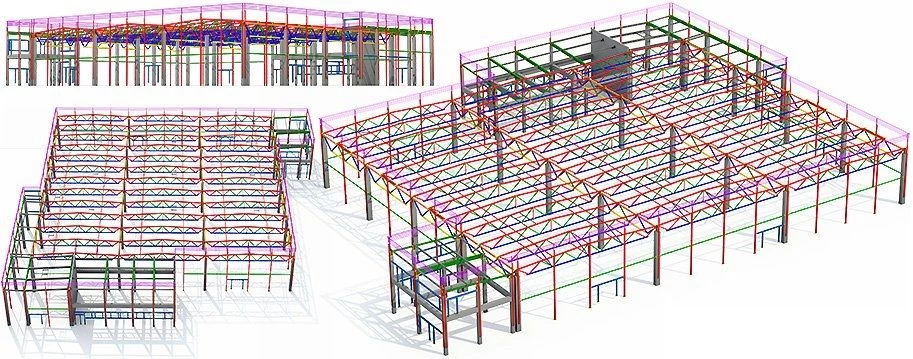

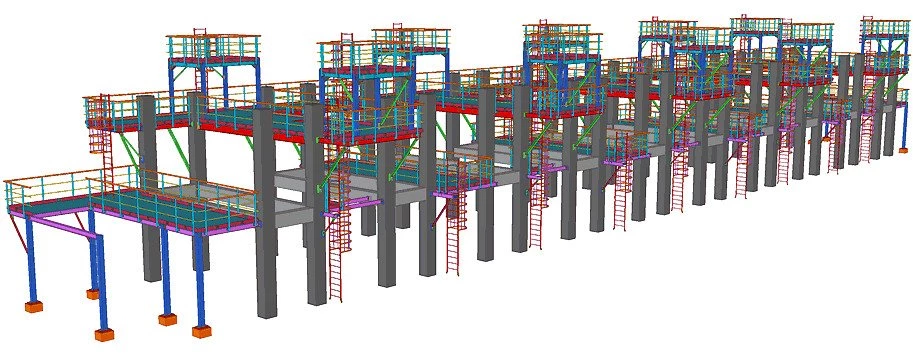

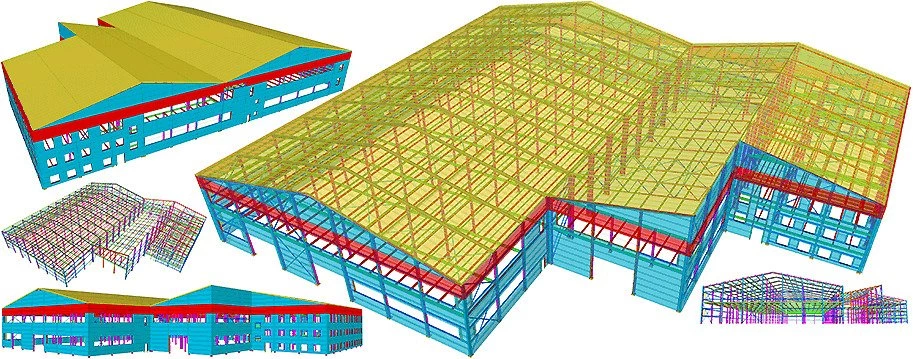

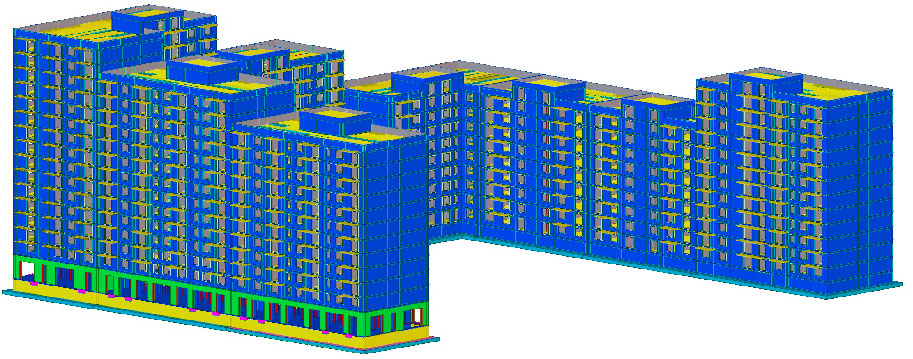

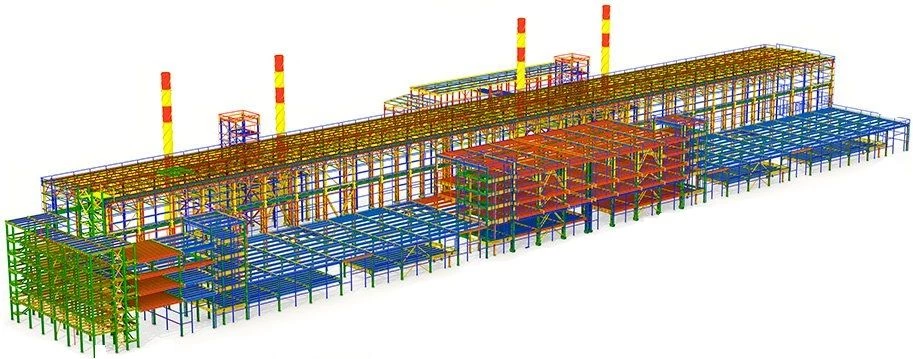

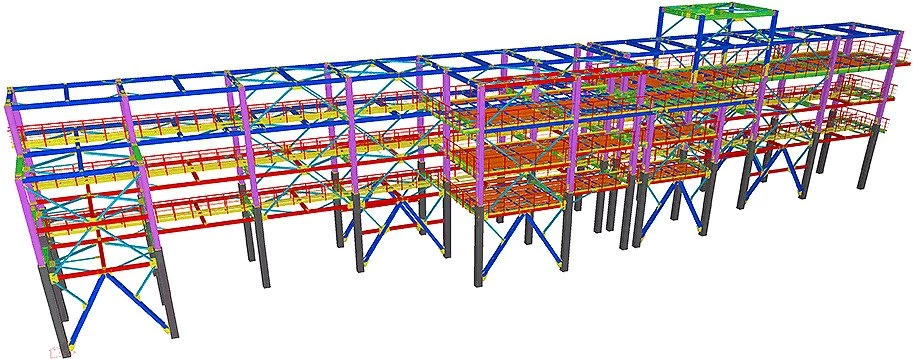

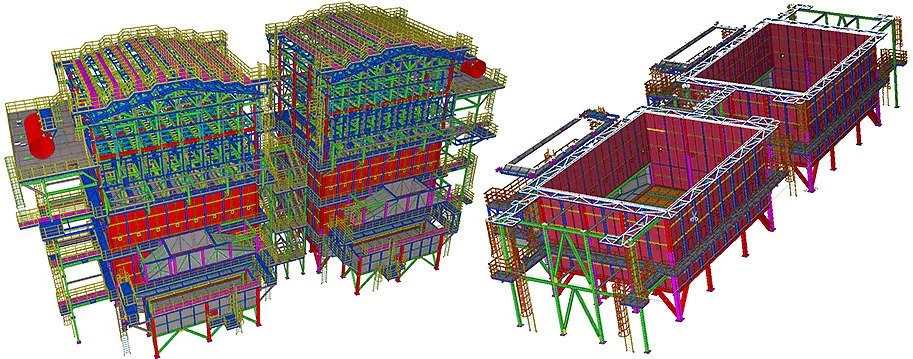

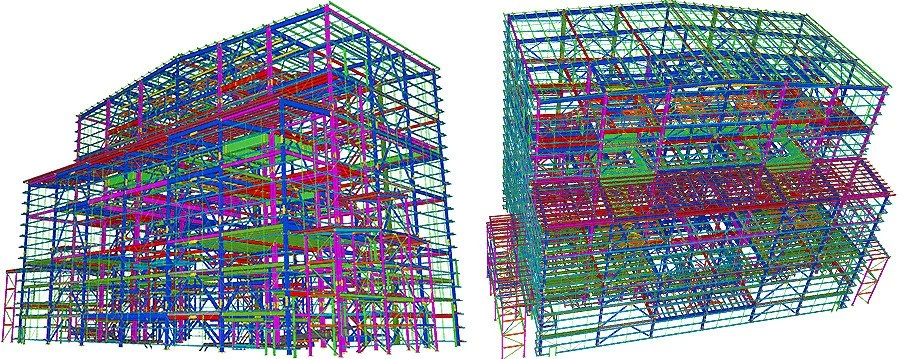

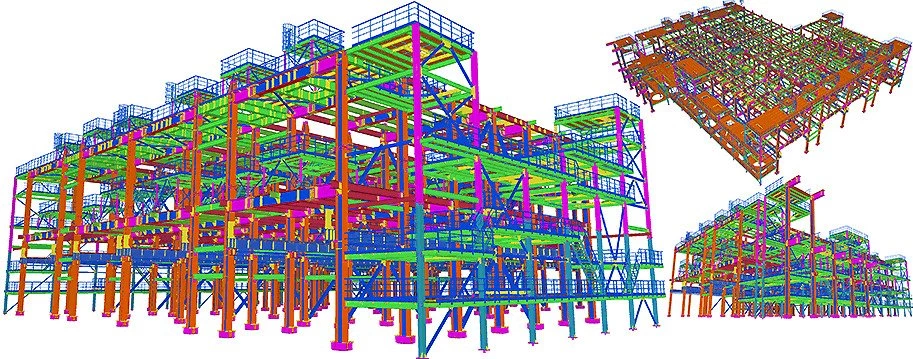

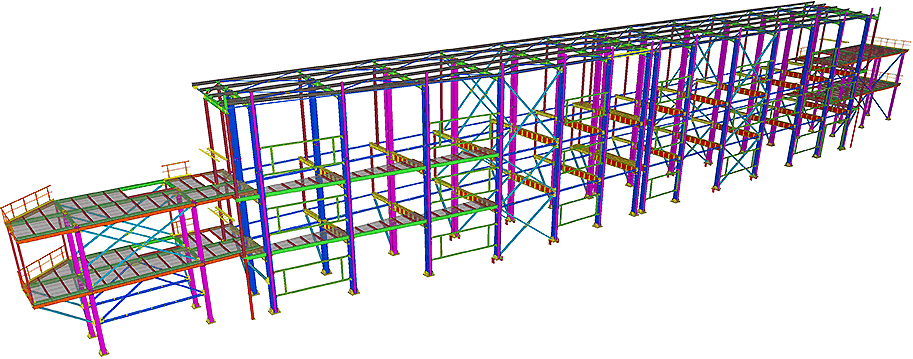

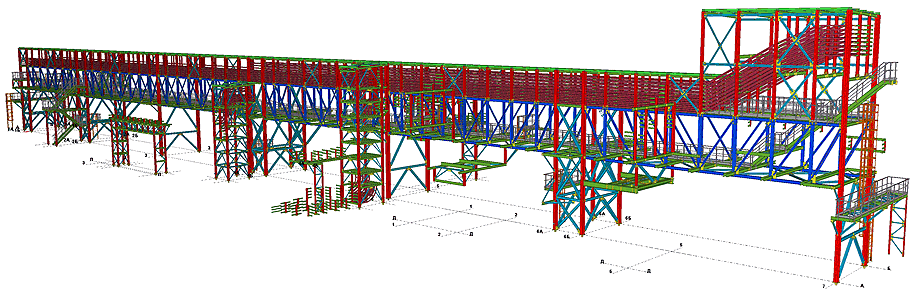

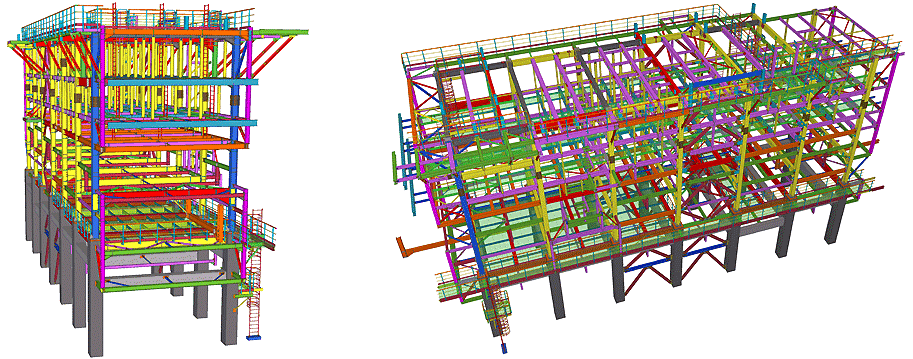

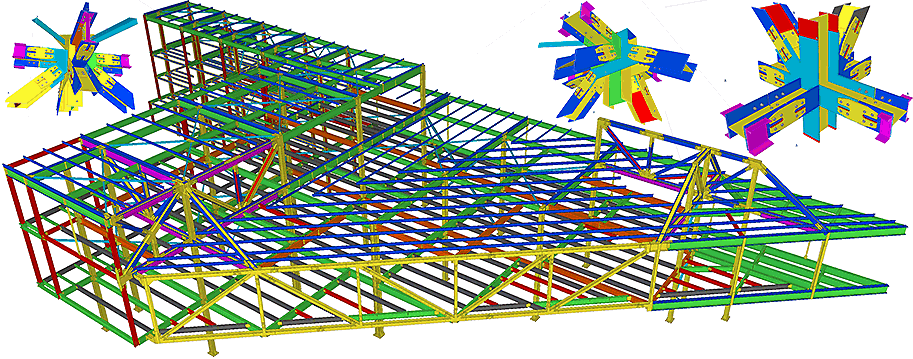

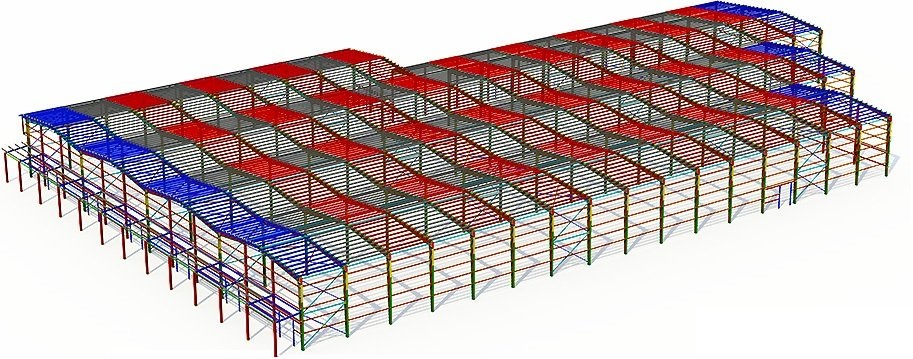

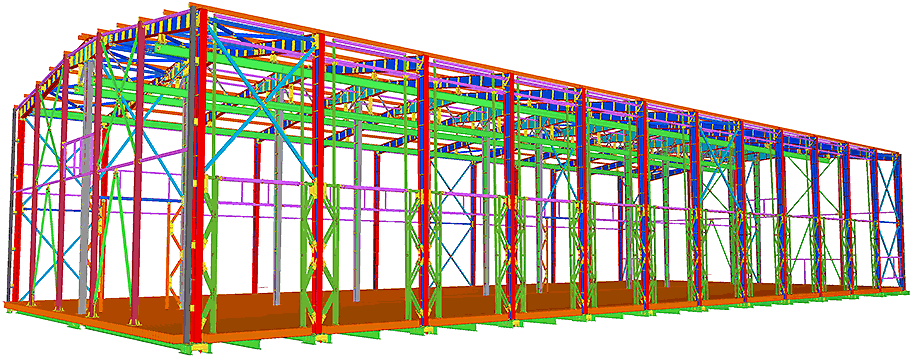

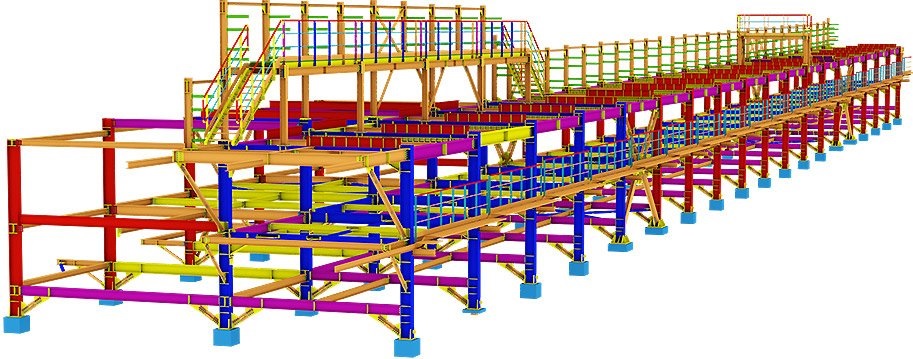

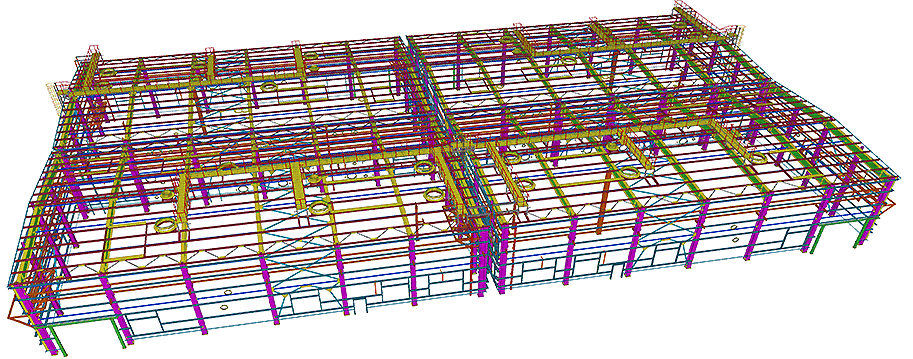

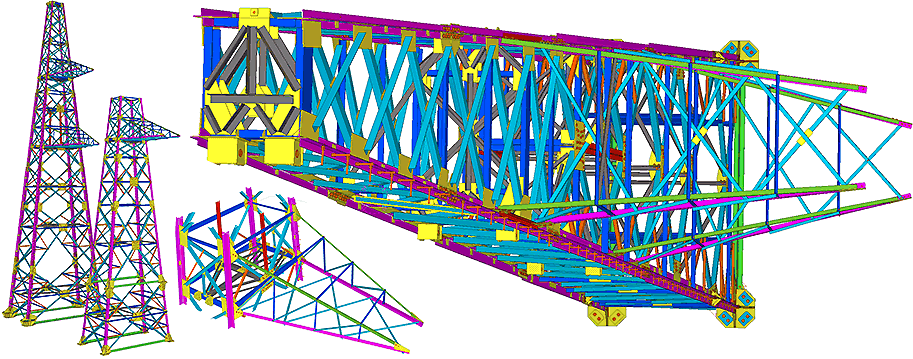

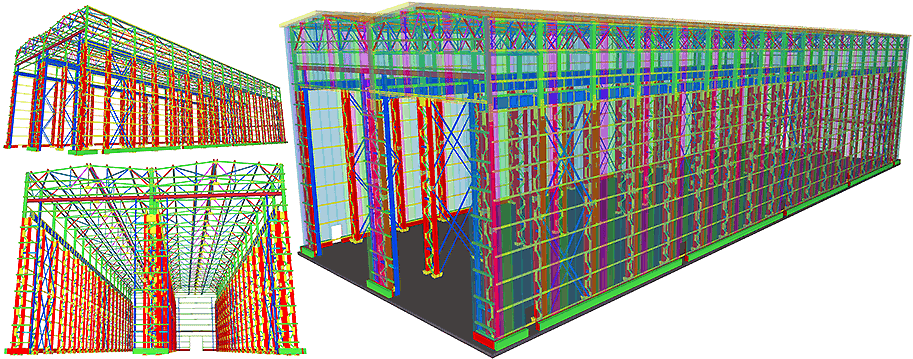

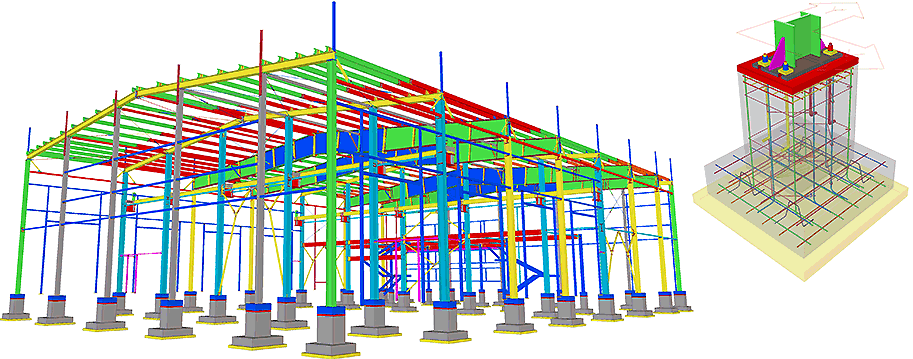

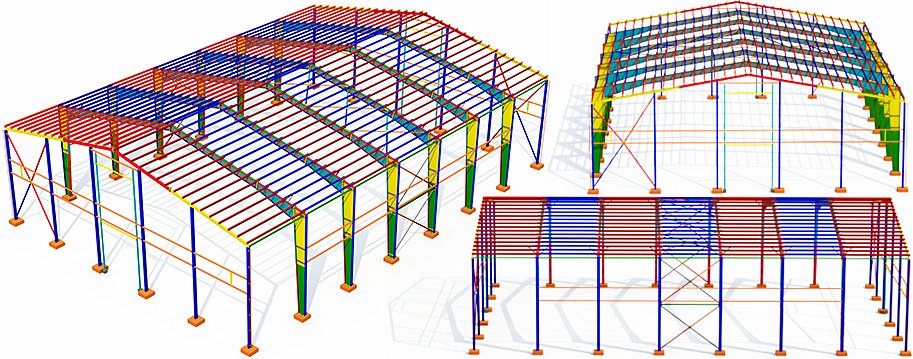

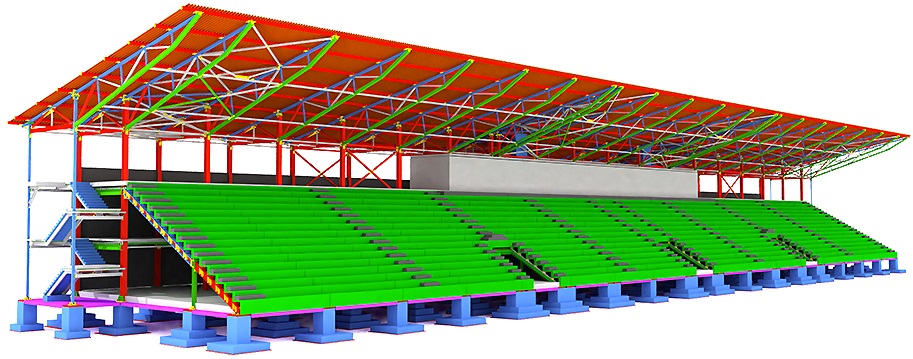

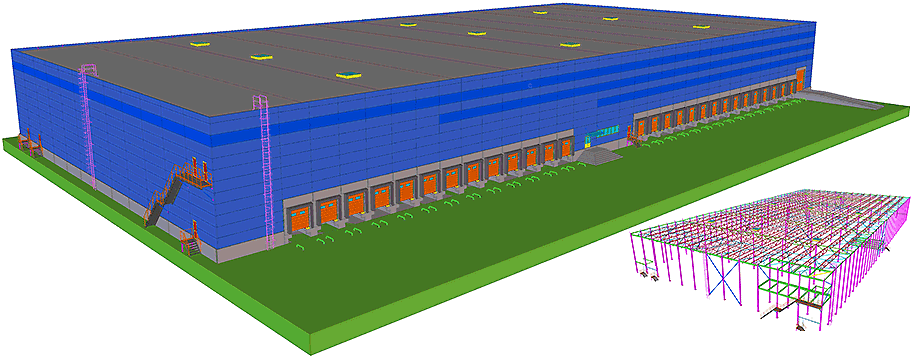

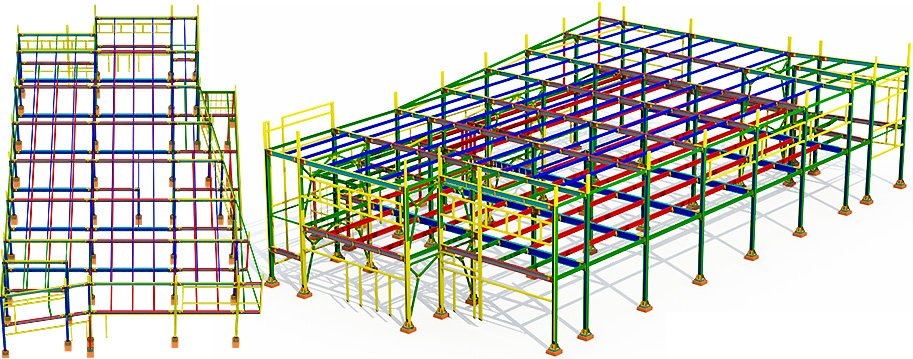

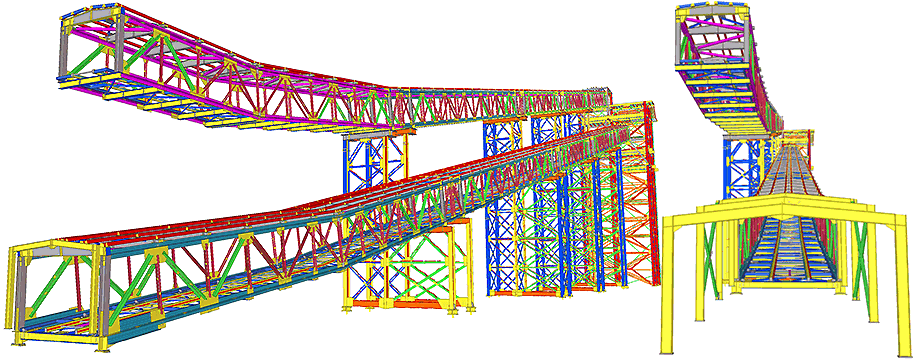

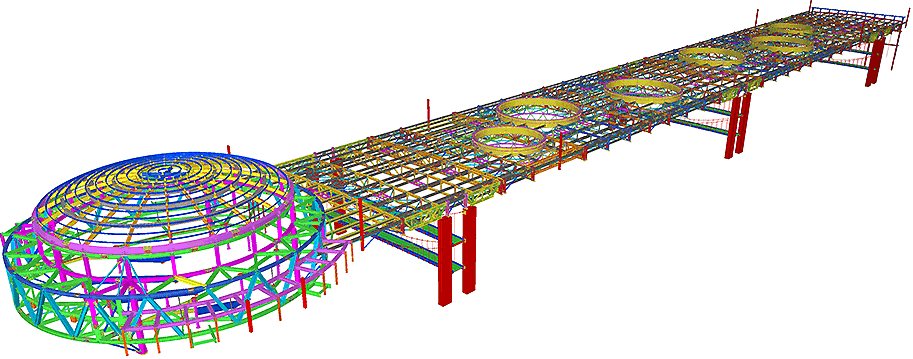

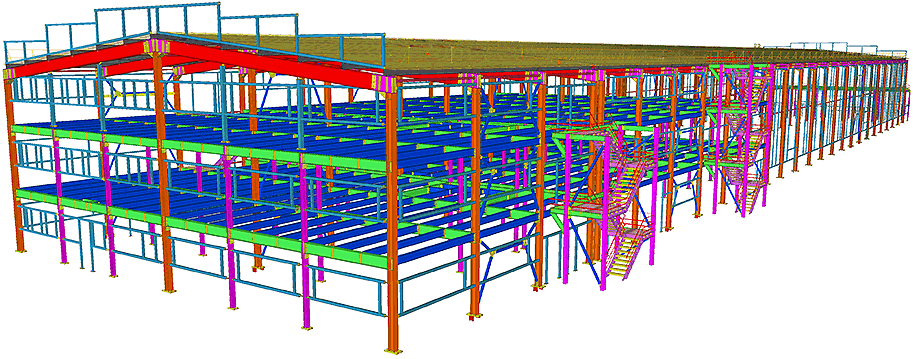

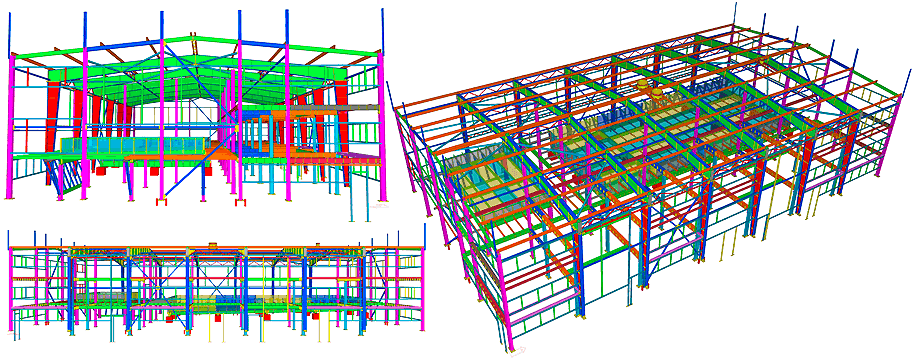

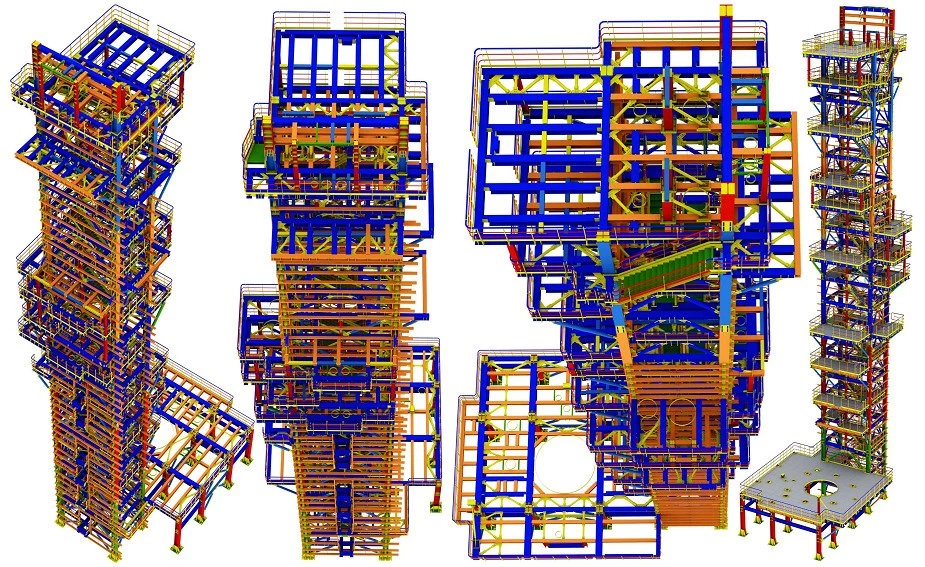

TopEngineer provides leading engineering services being innovative Structural Steel Detailing, Rebar Detailing, BIM Modelling, Joints Calculation and Structures Optimization company, committed to provide high quality services at any range and depth of steel and concrete structures to the commercial and industrial sectors.

We provide our services and solutions on a global scale, present in United States of America and European countries. Our international reach, industry expertise guarantees clean, accurate and comprehensive deliverables on schedule, with account for country- specific legislation and standard detailing practices.

Our Mission

Our goal is to continue to be the top leading steel detailing provider, and to become the industry’s first and only choice by developing excellent long-term relationships with our clients. Thus, our team is mostly concerned with getting your structure drawn right, instead of simply drawn quickly, ensuring that the final product is complete. We strive for 100% client satisfaction. Your success is our success!